What is a Swiss Machine?

A Swiss machine, also called a Swiss-style lathe or Swiss-type CNC lathe, is a marvel of precision engineering. Originally developed in Switzerland during the 19th century to produce intricate watch components, these machines have evolved into indispensable tools for industries requiring high-precision manufacturing. Think about the tiny screws in a wristwatch or the delicate surgical instruments used in operating rooms—Swiss machines excel at creating these types of parts.

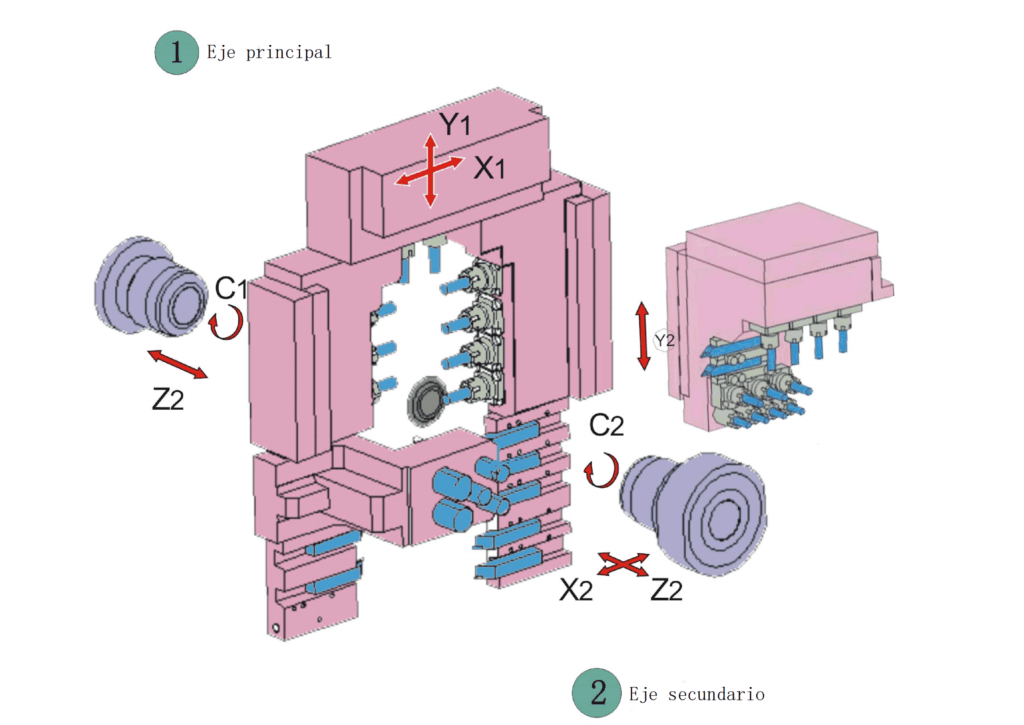

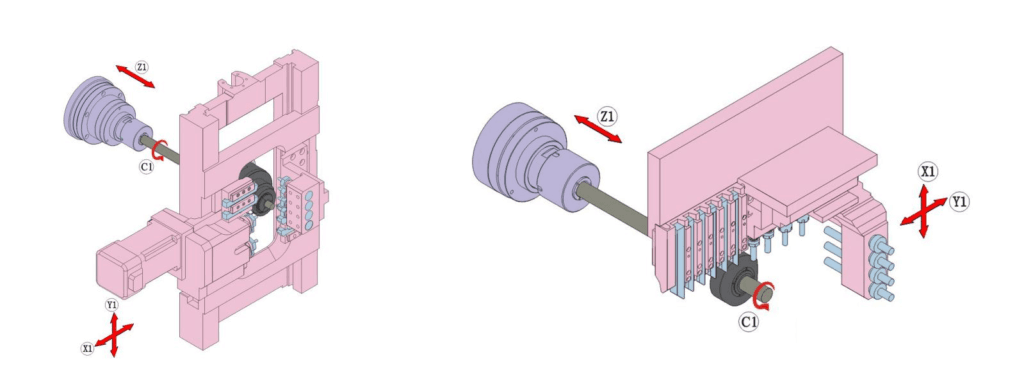

What sets a Swiss machine apart is its sliding headstock and guide bushing system. Unlike traditional lathes, where the workpiece remains stationary and the cutting tool moves, Swiss machines allow the workpiece to slide along its axis while being supported by the guide bushing. This design minimizes deflection and vibration, making it perfect for machining long, slender parts with extreme accuracy. Additionally, Swiss machines often feature multi-axis capabilities, enabling simultaneous turning and milling operations. This means they can handle complex geometries in a single setup, saving both time and resources.

For example, in the medical industry, Swiss machines are used to manufacture bone screws with tolerances as tight as 0.0002 inches. This level of precision ensures that these screws fit perfectly into orthopedic implants, reducing complications during surgeries.

What is a CNC Lathe?

A CNC lathe is the workhorse of modern manufacturing. It’s a versatile machine tool that uses computer numerical control to automate tasks like turning, threading, and boring. Picture it as a highly skilled craftsman that can churn out identical parts with incredible speed and accuracy.

In a CNC lathe, the workpiece is clamped and rotated by the spindle while stationary cutting tools perform machining operations. This setup makes it ideal for creating cylindrical components like shafts, bushings, and pipes. Some advanced CNC lathes even come with live tooling capabilities, allowing them to perform secondary operations like drilling or milling without needing a separate machine.

Take the automotive industry as an example: CNC lathes are used to produce engine components like crankshafts and camshafts. These parts must meet strict quality standards to ensure engine performance and longevity. The ability of CNC lathes to deliver consistent results across large production runs makes them indispensable in such applications.

The Importance of CNC Lathe in Modern Manufacturing

CNC lathe are not just tools; they’re problem-solvers for modern manufacturers. Their ability to produce complex parts with minimal error has revolutionized industries ranging from aerospace to consumer electronics.

One of their biggest advantages is repeatability. Once programmed, a CNC lathe can produce thousands of identical parts with micrometer-level accuracy. This consistency is crucial for industries like medical devices, where even minor deviations can have life-or-death consequences.

CNC lathes also shine in terms of flexibility. Need to switch from producing one part design to another? With just a few clicks to update the program, you’re ready to go—no need for extensive retooling or downtime. This adaptability makes them ideal for businesses handling diverse product lines or custom orders.

Additionally, CNC lathes optimize material usage by machining parts directly from bars or tubes fed into the spindle. This reduces waste and lowers costs—a critical factor when working with expensive materials like titanium or Inconel alloys.

Differences in Machining Principles

The core difference between Swiss machines and CNC lathe lies in how they handle the workpiece:

- Swiss Machines: The workpiece moves along its axis while being supported by a guide bushing close to the cutting tool. This minimizes deflection and allows for precise machining of long or thin parts. For instance, manufacturing a 10-inch-long medical implant with a diameter of just 0.25 inches would be nearly impossible on a traditional lathe due to deflection issues—but it’s routine work for a Swiss machine.

- CNC Lathes: The workpiece remains stationary as it rotates on the spindle while the cutting tool moves along various axes to perform machining tasks. This approach works well for larger or shorter parts where deflection isn’t a concern.

Performance Comparison

Precision and Surface Quality

Swiss machines are unmatched when it comes to precision. Thanks to their guide bushing system, they can achieve tolerances as tight as 0.0002 inches while delivering excellent surface finishes. This makes them ideal for industries like aerospace and medical devices where perfection is non-negotiable.CNC lathe also offer high precision but are slightly less accurate than Swiss machines. However, they’re more than capable of meeting the requirements for most industrial applications.

Efficiency

Swiss machines excel at multitasking. Their multi-axis capabilities enable simultaneous turning and milling operations, drastically reducing cycle times for complex parts. For example, producing a dental implant might take 30 minutes on a traditional lathe but only 10 minutes on a Swiss machine.CNC lathes are efficient too but may require additional setups or secondary operations for similar results.

Material Utilization

Swiss machines minimize material waste by supporting the workpiece close to the cutting area. This is particularly advantageous when working with expensive materials like gold or titanium—every millimeter saved translates into cost savings.

Swiss Machine and CNC Lathe Application Differences

Swiss Machine

These are best suited for:

- Small-diameter parts (under 38mm).

- Long components with high length-to-diameter ratios.

- Precision industries like medical (e.g., surgical screws), electronics (e.g., connectors), and watchmaking.

CNC Lathe

These excel in:

- Larger or shorter components.

- Applications requiring diverse machining operations.

- Industries like automotive (e.g., shafts), aerospace (e.g., turbine blades), and oil & gas.

Cost and ROI Analysis

Swiss machines come with higher upfront costs due to their advanced features but deliver excellent ROI through reduced cycle times, lower material waste, and higher production efficiency. They’re particularly valuable for high-volume production of precision parts where every second counts.CNC lathes are more affordable initially and better suited for medium-volume production runs or larger components. Their simpler design translates into lower maintenance costs but may require more operator intervention compared to Swiss machines.

Key Differences

Swiss machines prioritize precision for small, complex parts through innovative designs like sliding headstocks and guide bushings. Conversely, CNC lathes offer versatility across a broader range of part sizes with simpler setups but slightly lower accuracy.

Choosing between these two depends on your specific manufacturing needs—whether it’s high-volume precision or flexible part production across diverse applications!