- Need help?

- Contact Us Now

Jianke's CNC Swiss-type lathes are known for their superior machining accuracy and are suitable for industries that require high precision, such as aerospace and medical equipment manufacturing.

These lathes support the machining of multiple materials and complex parts, meeting diverse needs from automotive parts to communications equipment.

Jianke holds more than 60 patents and continues to maintain a leading position in the field of technological innovation to ensure that products are competitive in the market.

The company provides comprehensive solutions such as production line optimization and equipment maintenance to ensure that customers receive the best support and services during use.

Read More

Read More

Read More

Read More

Read More

Read More

Read More

Read More

Read More

Support Rotary Guide bush/Without guide bush changeable modes. When using rotary guide bush mode, it is suitable for processing shaft workpieces, with a single feeding length of 195~200mm and support for multiple feeding. The tail material length is 180mm; When using without guide bush mode, it is suitable for processing short workpieces with a length to diameter ratio of less than 1:2.5, which can minimize the length of the tail material. The length of the tail is 50mm

Adopting Japan oil cooled electric spindle technology, independently designed and developed, we have overcome the core problems of the spindle of the Swiss CNC lathe machine. Compared with other electric spindles of the same power, we have stronger rigidity and torque force, and more stable processing accuracy. Using NSK bearings to extend spindle life and radial stability.

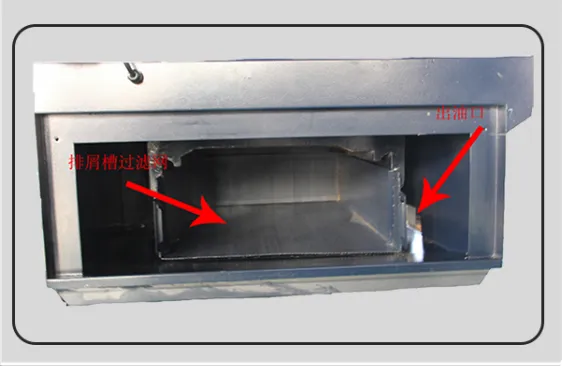

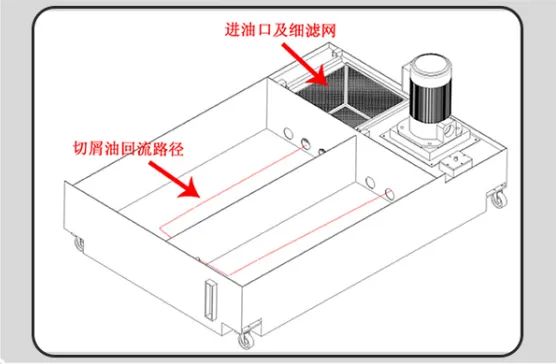

The waste collection box adopts a separation platform for chip collection, allowing the cooling oil to undergo preliminary buffering and cooling on the chip collection platform for preliminary oil chip separation; Then enter the cutting oil tank with a volume of 250L from the oil drain. The cutting oil tank is equipped with multi-channel filter screens and oil return baffles to extend the return path and separate /filter oil chips as far as possible; Make the oil temperature reach full Free cooling and reduce the debris entering the oil pump, so as to extend the service life of the oil pump.

Jianke's full series of dual spindle Swiss CNC Lathe come standard with a collection method of front discharge products. When the length of the workpiece is less than 90mm, the front material receiving box can be used for collection and the product can be sent out through a built-in conveyor belt. When the product length is more than 90mm, the rear discharge method can be selected, and the product is ejected through the center of the sub spindle through a slot on the side sheet metal of the equipment.

The JIANKE MA series lathes comes standard with 2 ER11+2 ER16. The 2 ER16 side rotary power tools supporting modular expansion functions that can be added with additional functions and tool positions according to demand. (The plug-in modules are all for options and if needed for such modules, please list them in the contract/quotation.)

Reflux type + multi-channel filtration oil tank

The fuel tank adopts a guided reflux method to avoid the heat just entering the fuel tank.

The oil is immediately sucked by the oil pump, so that the cutting oil has sufficient buffer time.

Reduce oil temperature, reduce the impact of oil temperature on the processing accuracy of products;

A coarse and fine filter mesh groove is arranged at the oil inlet of the fuel tank, and each

A total of three filtering network cards are placed at the gate (three in total), multi-channel filtering

Prevent chips from entering the oil pump.

All sheet metal seams are chamfered and grooved to prevent accidents.

The leaked oil returns to the equipment, preventing the oil mist from leaking.

Workshop environmental pollution.

High-strength toughened glass is installed on both sides of the processing area,

It ensures the safety and observability of operators.

(**Single-axis models only have one side**)

A plurality of external signal line interface holes are reserved in the sheet metal shell, so that

Customers can add other auxiliary equipment to the equipment to avoid pulling wires.

Causing the equipment electrical cabinet box and the wiring around the site to be messy. (For example High-pressure oil pump, chip ejector, oil mist purifier, oil-water separator and other auxiliary equipment)

In the sheet metal shell, the high-pressure oil pump inlet oil hole is pre-opened, which is convenient.

The customer can access the high-pressure oil pump and oil pipe according to their own needs later.

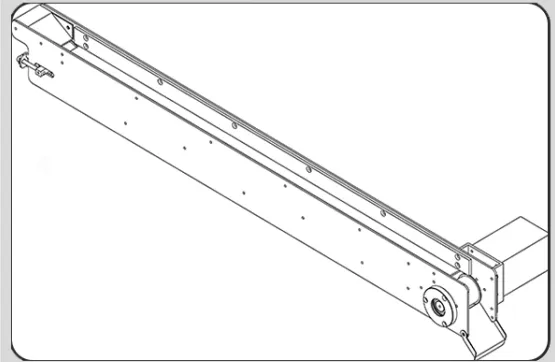

All dual-spindle models are equipped with output transmission belt to avoid products

The surface is scratched by the mutual collision of the output.

(* *The single spindle is a telescopic receiving box**)

Equipped with LED three-color light, can be set as the root needs

In bright / flash mode. Equipped with a buzzing sound to make patrols

The officers first spotted an abnormal device alarm.

We value your privacy

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies.

Welcome to contact Jianke Machinery, we look forward to discussing cooperation opportunities with you. Whether you want to learn more about the product, get technical support, or discuss business cooperation, our team is always ready to provide you with professional and efficient services.