- Need help?

- Contact Us Now

The MR32-5II is an advanced dual spindle CNC centering machine designed to deliver high precision and efficiency in processing cylindrical workpieces. With its dual spindle configuration, the MR32-5II allows for the simultaneous centering of two workpieces, significantly boosting throughput. The machine is equipped with a precision CNC control system and servo motor driven spindles, ensuring accurate and consistent results. Its intuitive touch screen interface simplifies operation and monitoring, making it accessible for operators of all skill levels. The compact design of the MR32-5II makes it ideal for workshops with limited space, offering both efficiency and precision in a small package.

| Double spindle Swiss CNC lathe MR32-5II | ||||

| System | Taiwan SYNTEC | Syntec210TB-A | ||

| Control channel | Double channel | |||

| Minimum setting unit | 0.001mm | |||

| Machining | Max processing diameter | 32 mm | ||

| Max processing length at one time | With guide bush | 260mm | ||

| Without guide bush | 1:2.5D(Dia:Lenth) | |||

| Main spindle max drilling Dia | Main spindle axial | ER20 | Φ13mm | |

| ER16 | Φ10mm | |||

| ER11 | Φ7mm | |||

| Main spindle max tapping Dia | Main spindle axial | ER20 | M12 | |

| ER16 | M8 | |||

| ER11 | M6 | |||

| Power head max drilling Dia | Radial | Φ10mm | ||

| Power head max tapping Dia | Radial | M8 | ||

| Sub spindle max drilling Dia | Sub spindle axial | Φ10mm | ||

| Sub spindle max tapping Dia | Sub spindle axial | M8 | ||

| Tool | Tool seat arrangement | Upside tool seat | ||

| Main spindle turning tool | 6 pieces | 6 pieces 16X16mm | ||

| Main spindle side roatry power head | 5 pieces | 5 pieces ER16 | ||

| Main spindle end face fixed tool seat | 4 pieces | 3 pieces ER11/ER16+1 piece ER20 | ||

| Sub spindle end face fixed tool seat | 4 pieces | ER11/ER16 | ||

| Main Spindle | Main/sub spindle type | Built-in oil-cooled electric spindle | ||

| Main/sub spindle speed | 8000rpm/min | |||

| Main/sub spindle index | 0.001° | |||

| Main/sub spindle hole Dia | 34mm | |||

| Main/sub spindle center height | 1060mm | |||

| Motor power | Main Spindle power (rated/maximum) | 3.5kw/6.0kw | ||

| Sub Spindle power (rated/maximum) | 3.5kw/6.0kw | |||

| Side rotary head motor power | 1.7kw | |||

| Side rotary head speed | 5000rpm/min | |||

| No. of moving axis | 5 axis | X1、Y1、Z1、X2、Z2 | ||

| Rapid feeding speed | 24m/min | |||

| Moving axis motor power | 0.75kw | |||

| Other | Parts receive device | Short bar | Parts conveyor collect parts | |

| Long bar | Sub spindle backside collect parts | |||

| Power capacity | 20kw | |||

| Air pressure | Above 0.4MPa | |||

| Cutting oil tank capacity | 286L | |||

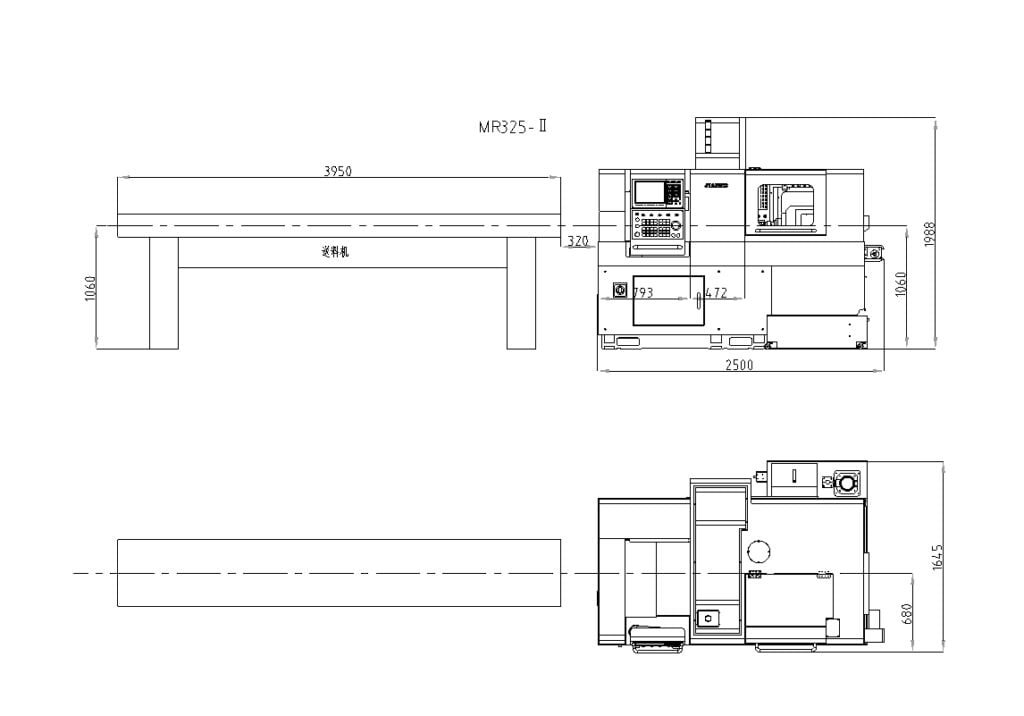

| Machine size(L*W*H) | 2.47m×1.6m×2.0m | |||

| Lathe Weight | 3880KG | |||

Read More

Read More

Read More

Read More

Read More

Read More

We value your privacy

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies.

Welcome to contact Jianke Machinery, we look forward to discussing cooperation opportunities with you. Whether you want to learn more about the product, get technical support, or discuss business cooperation, our team is always ready to provide you with professional and efficient services.