- Need help?

- Contact Us Now

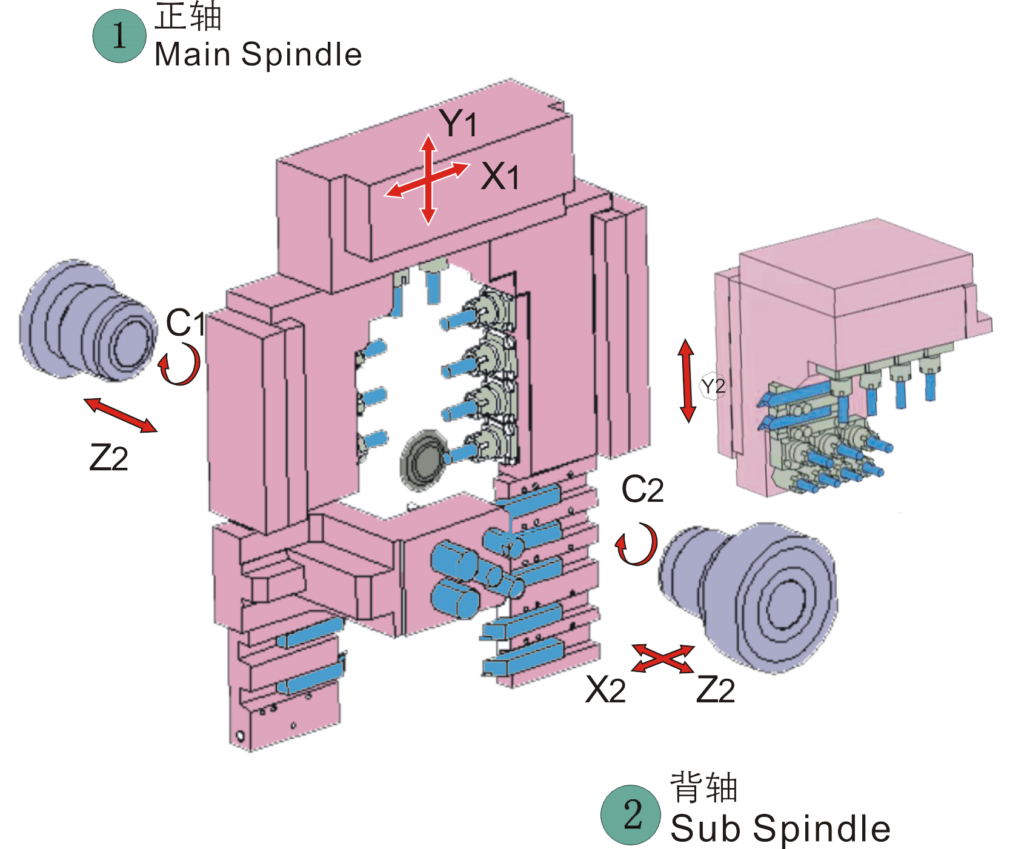

The Dual Spindle Centering Machine DT38-6S is a high-performance CNC machine designed for high-speed and precise part production. Its dual spindle system allows two workpieces to be processed simultaneously, which significantly reduces cycle times and increases output. With its advanced 6-axis control, this machine is capable of handling complex tasks and delivering consistent, high-quality results. The machine’s compact design and user-friendly interface make it an excellent choice for workshops seeking to improve productivity without sacrificing floor space.

| Double Spindle Swiss CNC Lathe DT38-6S | |||

| System | Taiwan SYNTEC | Syntec210TB-A | |

| Control channels | Dual channel | ||

| Minimum setting unit | 0.001mm | ||

| Machining Ability | Max processing diameter | 42 mm | |

| Maximum single feeding length | Rotary guide bush | 150mm(Optional) | |

| Without guide bush | 1:2.5D(Dia:Length) | ||

| Main spindle max drilling Dia | axial(main spindle) | Φ23mm | |

| Main spindle tapping Dia | axial | M16 | |

| Rotary tools max drilling Dia | radial | Φ10mm | |

| Rotary tools max tapping Dia | radial | M8 | |

| Sub spindle max drilling Dia | Axial(sub spindle) | Φ10mm | |

| Sub spindle max tapping Dia | axial | M8 | |

| Tools | Tool base arrangement | Gantry type | |

| Main spindle O.D. tools | 7 pieces | 16X16mm | |

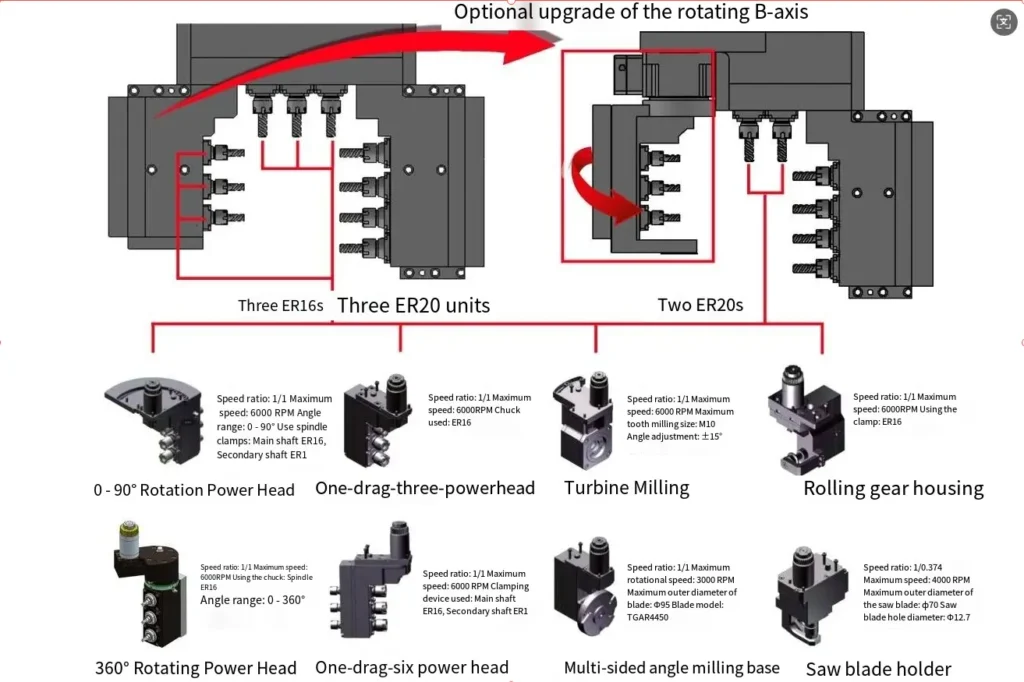

| Main spindle side rotary live tools | 10 pieces | 7*ER20+3*ER16 | |

| Main spindle end face fixed tools base | 5 pieces | 2*ER20+3*ER16 | |

| Sub spindle end face fixed tool base | 4 pieces | 1*ER20+3*ER16 | |

| Sub spindle end face rotary tools | 3 pieces | 3*ER20 | |

| Sub spindle side rotary tools | 4 pieces | 3*ER20+1*ER16 | |

| Sub spindle O.D. turning tools | 2 pieces | 12X12mm | |

| Spindles | Main/Sub spindle type | Internal oil cooling electric spindle | |

| Main/Sub spindle speed | 6000rpm/min | ||

| Main/Sub spindle indexing | 0.001° | ||

| Main/Sub spindle through hole Dia | 44mm | ||

| Main/Sub spindle height | 1090mm | ||

| Motors | Main spindle power(Rated/Max) | 11kw/18.5kw | |

| Sub spindle power(Rated/Max) | 11kw/18.5kw | ||

| Main/Sub spindle rotary tools motor power | 3.1kw/1.1kw | ||

| Main spindle side rotary tools speed | ER16*3 pieces | 8000rpm/min | |

| ER20*7 pieces | 6000rpm/min | ||

| Sub spindle rotary tools speed | Side rotary tools | 7500rpm/min | |

| End face rotary tools | 8000rpm/min | ||

| Moving axis | 6 axis | X1、Y1、Z1、X2、Y2、Z2 | |

| Rapid feeding speed | X1、Y2 | 24m/min | |

| Y1、Z1、X2、Z2 | 32m/min | ||

| Motor power of moving axis | 1.1kw | ||

| Others | Parts collector | Short parts | Belt conveyor to collect parts |

| Long parts | rear ejection from sub spindle | ||

| Power capacity | 34.8kw | ||

| Air pressure | 0.4MPa or above | ||

| Capacity of machining oil tank | 340L | ||

| Lathe size | 2.6m×1.5m×2.28m | ||

| Lathe weight | 3900KG | ||

Q: What materials can the DT38-6S machine process?

A: The DT38-6S is capable of processing a variety of materials including metals, plastics, and composites.

Q: How many spindles does the machine have?

A: The machine is equipped with dual spindles, allowing simultaneous operation on two parts.

Q: What is the maximum workpiece size it can handle?

A: The machine can handle workpieces up to 38mm in diameter.

Q: Is the machine suitable for high-volume production?

A: Yes, the DT38-6S is designed for high-speed, high-volume production with its dual spindle system.

Q: Does the machine require a lot of floor space?

A: No, the machine has a compact structure, ideal for workshops with limited space.

Q: Is technical support available for installation and training?

A: Yes, we offer full technical support for installation, setup, and training.

Read More

Read More

Read More

Read More

Read More

Read More

We value your privacy

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies.

Welcome to contact Jianke Machinery, we look forward to discussing cooperation opportunities with you. Whether you want to learn more about the product, get technical support, or discuss business cooperation, our team is always ready to provide you with professional and efficient services.