Did you know? In the world of 3-axis CNC lathe, the spindle unit is like the engine-it determines the “heartbeat” and “pulse” of the entire machine. Whether it’s high-speed cutting or precision machining, the spindle unit plays a crucial role. As a manufacturer, understanding the structure, performance, and maintenance of the spindle unit not only boosts equipment efficiency but also helps customers make informed purchasing decisions.

Today, let’s talk about the core component of 3-axis CNC lathe-the spindle unit. Let’s unveil its mysteries and help you master this “secret weapon.”

Introduction to 3-Axis CNC lathe

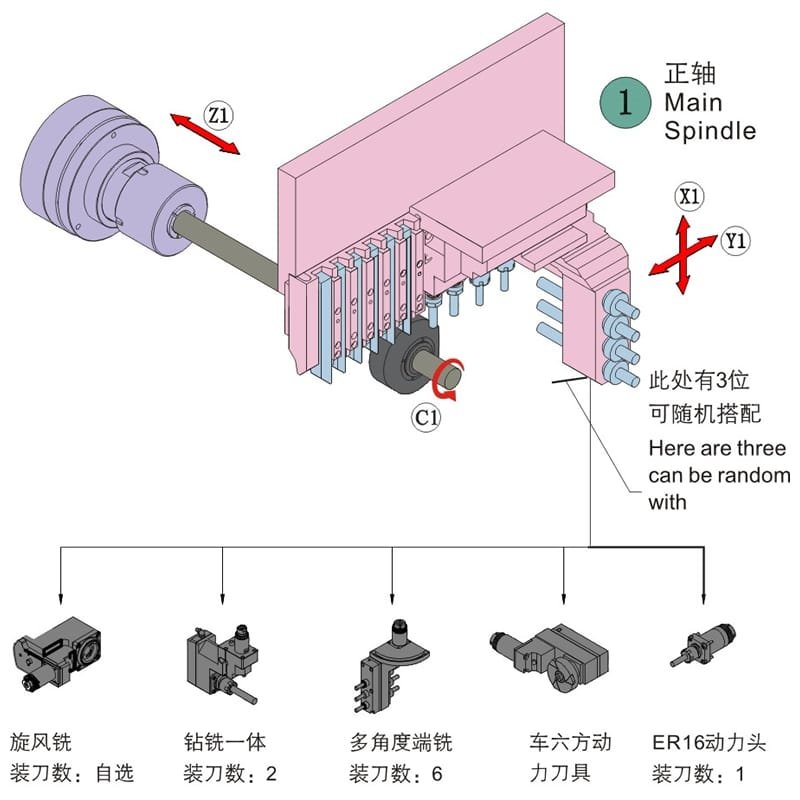

As the name suggests, a 3-axis CNC lathe can precisely control movement in the X, Y, and Z directions. These machines are widely used for parts processing, mold manufacturing, and mass production.

- X-axis: Moves left and right

- Y-axis: Moves forward and backward

- Z-axis: Moves up and down

The coordinated movement of these three axes enables the machine to handle complex machining tasks. The spindle unit is responsible for rotating the tool or workpiece and is key to the machining process.

Imagine this: without the spindle unit, a CNC machine is like a heartless body-no matter how advanced the control system is, it can’t perform.

Components and Types of Spindle Units

The spindle unit may look simple, but it actually consists of several key parts:

- Spindle body: Includes spindle bearings and housing, ensuring stable and precise rotation.

- Cooling system: Prevents the spindle from overheating and extends its lifespan.

- Drive methods:

- Belt drive: Traditional and economical, suitable for medium and low-speed machining.

- Direct drive: High transmission efficiency, ideal for high-speed, high-precision machining.

- Motorized spindle: Integrated motor, compact structure, and fast response.

Different types of spindle units are suited for different machining needs. Choosing the right spindle unit is key to improving machine performance.

Key Technical Parameters of CNC lathe Spindle Units

Understanding the technical parameters of spindle units helps you match customer needs more accurately. Here are some core indicators:

| Parameter | Description | Impact |

|---|---|---|

| Speed range | e.g., 45–4000 rpm | Determines machining speed and material suitability |

| Power & torque | Output capacity of spindle motor | Affects cutting force and machining efficiency |

| Spindle taper | Such as BT, HSK, etc. | Affects tool compatibility and tool change speed |

| Precision index | Positioning and repeatability | Directly relates to the dimensional and shape accuracy of parts |

Performance Advantages of Spindle Units

Why do customers rave about spindle units? Here are a few reasons:

- High speed and precision: High speeds enable faster machining, and precision ensures product quality.

- Stable and durable: High-quality bearings and cooling systems ensure long-term operation without overheating or vibration.

- Multi-material adaptability: Easily handles metals, plastics, wood, and more.

It’s like the engine of a sports car-powerful and reliable, enabling the machine to perform at its best.

Application Cases of CNC lathe Spindle Units

Let’s see how spindle units perform in real-world scenarios:

- Automotive parts machining: Requires high precision and strength; the spindle unit ensures dimensional stability.

- Mold manufacturing: Complex surface machining relies on the spindle’s rigidity and precision.

- Electronics casing production: Fine surface finishing depends on the spindle’s high-speed operation.

Different applications have different requirements for spindle units. Choosing the right one can significantly improve machining efficiency.

Maintenance and Care of Spindle Units

Want your spindle unit to last longer? Maintenance is essential:

- Regular lubrication: Keeps bearings lubricated and reduces wear.

- Check the cooling system: Ensure coolant flows smoothly to prevent overheating.

- Bearing inspection and replacement: Address abnormal noise or vibration promptly.

- Keep the spindle clean: Prevent dust and debris from affecting operation.

Simple maintenance steps can greatly extend the spindle unit’s lifespan and avoid costly downtime.

Tips for Choosing a 3-Axis CNC lathe Spindle Unit

With so many spindle units available, how do you choose the right one? Here are a few tips:

- Clarify machining needs: Choose speed and power based on materials and processes.

- Focus on brand and after-sales service: Reputable brands offer more stable performance and timely support.

- Consider cost-effectiveness: Don’t just look at price-performance and durability matter more.

Choosing the right spindle unit ensures your machine delivers maximum value. Your customers will be satisfied, and you’ll have peace of mind.

—

The spindle unit is not only the “heart” of a 3-axis CNC lathe but also the key to improving machining efficiency and quality. Understanding its structure, performance, and maintenance helps you create more competitive products.

If you’re looking for high-quality 3-axis CNC lathe spindle units, feel free to contact us. Our professional team will provide the best solutions to help your production reach new heights!

Want to learn more about 3-axis CNC lathe and their components? Visit our website or send us an inquiry let’s start a new chapter of efficient machining together!