Hello there! As a professional CNC machine manufacturer, we understand just how vital rotary axis configurations are to machining performance. The rotary axis not only determines the flexibility and precision of your machine, but also directly affects production efficiency and part quality. Today, we’ll walk you through the main types of rotary axis configurations in CNC machine, analyze their unique advantages and suitable applications, and help you make informed choices when purchasing. Whether you’re machining small precision parts or large, complex structures, this article will offer you practical technical insights.

Core Types of CNC Machine Rotary Axis Configurations

Rotary axis configurations come in various forms, but the three main types are:

1. CNC machine Dual Rotary Table Structure (B+C Axes)

In this setup, the rotary axes are integrated into the worktable, typically with the B axis on the YZ plane and the C axis on the XY plane.

- Applications: Ideal for machining small precision parts, with a maximum load capacity usually not exceeding 200 kg.

- Advantages: High spindle rigidity, capable of handling heavy cutting loads-perfect for high-volume material removal.

- Tip: If your parts require high rigidity and precision, the dual rotary table structure is a great choice.

2. Dual Swivel Head Structure (B+C Axes)

Here, the rotary axes are built into the spindle head, usually with the B axis on the ZX plane and the C axis on the XY plane.

- Applications: Suited for large structural parts in industries such as aerospace, with load capacities of 500 kg or more.

- Advantages: Enables multi-face machining of large workpieces in a single setup, significantly boosting efficiency by reducing repeated clamping.

- Fun Fact: Imagine completing multiple faces of a large part in just one setup-saving time and labor, and doubling your efficiency!

3. Hybrid Structure (Single Rotary Table + Single Swivel Head)

This mixed configuration features a C axis on the worktable and a B axis on the spindle head.

- Applications: Perfect for medium-sized, complex curved parts, such as automotive molds and medical implants.

- Features: Strikes a good balance between machining range and equipment cost.

- Suggestion: If your project needs both versatility and budget control, this configuration is worth considering.

Key Technical Parameter Comparison

To help you quickly grasp the performance differences, here’s a comparison table:

| Parameter | Dual Rotary Table | Dual Swivel Head | Hybrid Structure |

|---|---|---|---|

| Positioning Accuracy | ±2″ | ±5″ | ±3″ |

| Max Rotational Speed | 50 rpm | 30 rpm | 40 rpm |

| Repeatability | 0.003 mm | 0.008 mm | 0.005 mm |

As you can see, the dual rotary table structure excels in positioning accuracy and repeatability, making it ideal for high-precision machining. While the dual swivel head structure offers slightly lower accuracy, it stands out for its load capacity and ability to handle large workpieces. The hybrid structure finds a sweet spot between performance and cost.

Mapping Configuration Choices to Machining Capabilities

Choosing the right rotary axis configuration depends on your machining needs:

Complex Surface Machining

- Five-axis simultaneous machining can achieve 0.01 mm-level accuracy for impeller blades-impressive, right?

- Swivel head structures are perfect for deep, narrow cavity parts, especially when the depth-to-diameter ratio is 5:1 or greater.

Batch Production Optimization

- Rotary table structures can reduce tool change times by up to 40%, significantly improving production efficiency.

- Hybrid configurations minimize cumulative errors from multiple repositionings, ensuring stable machining quality.

In summary: If you demand the highest precision, go for the dual rotary table. For large, complex parts, the dual swivel head is your best bet. If you need versatility and cost-effectiveness, the hybrid configuration is ideal.

Customer Selection CNC machine Flowchart

To help you decide quickly, here’s a simple selection process:

- Workpiece Size

- Small → Prioritize dual rotary table structure

- Large → Prioritize dual swivel head structure

- Precision Requirements

- High precision → Choose closed-loop control systems

- General precision → Semi-closed loop is sufficient

- Batch Size

- Large batches → Consider automatic tool changers

- Small batches → Manual or semi-automatic is fine

- Budget

- Higher budget → Go for high-performance configurations

- Limited budget → Hybrid structure for a balance of performance and cost

Industry Application Case Studies CNC machine

Let’s look at some real-world examples of how rotary axis configurations support different industries:

- Medical Devices: Dual rotary table structure used to machine joint implants, achieving a surface roughness of Ra0.2μm-ensuring comfort and durability for implants.

- Energy Equipment: Dual swivel head structure for turbine blade machining, with tolerances controlled within ±0.015 mm-significantly improving blade performance and lifespan.

The rotary axis configuration is a key factor in CNC machine performance. Different designs not only affect machining accuracy but also determine load capacity and application range. With this detailed analysis, you should now have a clearer understanding of each configuration’s strengths and be able to choose the right one for your machining needs.

If you’re looking for the ideal rotary axis configuration for your production line, contact us today! We offer professional technical support and customized solutions to help you boost your productivity and product quality. Don’t hesitate-your perfect CNC machine is just a message away!

Related Articles:

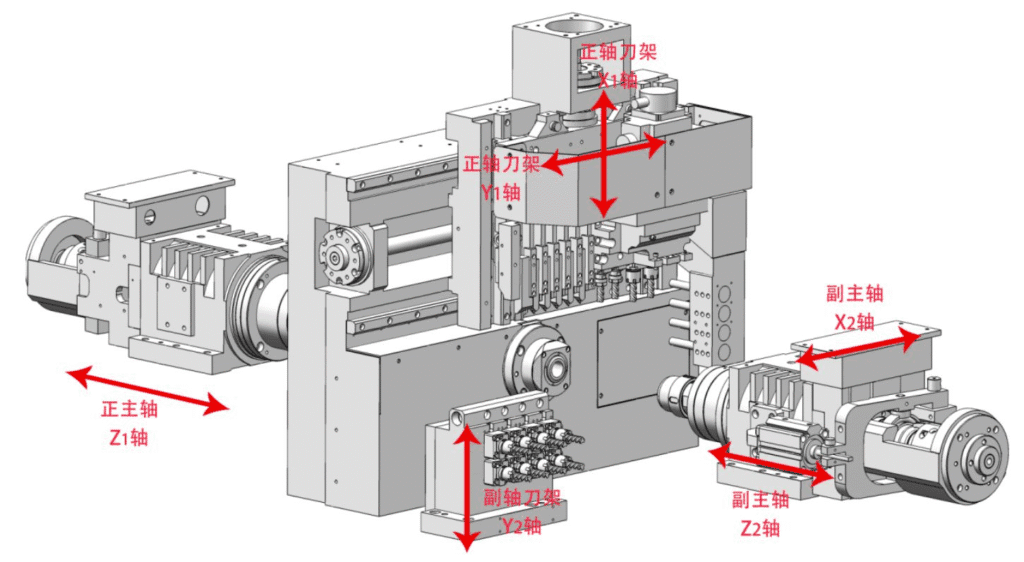

3-Axis CNC Lathe-Detailed Explanation of Turret/Turret System

Comparison of 3-Axis, 5-Axis, 6-Axis, and 9-Axis CNC Lathe