The Impact of Choosing the Right CNC Machine Tools on Project Success

The efficiency, precision and overall productivity of the right CNC machine tools are critical to project success.When it comes to project success, selecting the right CNC Lathe is crucial. These tools are not just pieces of equipment; they are the backbone of manufacturing processes. The right choice can lead to increased efficiency, improved product quality, and ultimately, greater profitability.

Key Factors

Selecting CNC machine tools involves several critical factors. Understanding these can help you make an informed decision.

- CNC Machine Tools Manufacturers: Researching reputable manufacturers is essential. Established CNC machine tools manufacturers often provide better support, warranties, and parts availability.

- CNC Machine Tools Market Trends: Keeping an eye on the CNC Lathe market can offer insights into new technologies and innovations that could benefit your projects.

- CNC Machine Tools Suppliers: A reliable supplier ensures that you have access to necessary parts and maintenance services. Building a relationship with suppliers can also lead to better pricing and support.

Economic Cost Factors

Cost is always a significant consideration in any project. When evaluating CNC machine tools, consider not only the initial purchase price but also the long-term operational costs.

- Initial Investment vs. Long-Term Savings: Sometimes, spending more upfront on high-quality CNC Lathe can save money in the long run due to reduced maintenance and higher efficiency.

- Return on Investment (ROI): Calculate the potential ROI by assessing how much time and resources the right tools will save during production.

Available Space and Operating Conditions

The physical space available for your CNC machine tools can greatly influence your choice.

- Footprint of the Machines: Ensure that the selected machines fit comfortably within your workspace without compromising safety or accessibility.

- Operating Conditions: Consider factors like temperature, humidity, and cleanliness of the environment where the machines will operate. Some CNC Lathe are better suited for harsh conditions than others.

Which is More Suitable: Economic or Standard CNC Machine Tools?

When deciding between economic and standard CNC Lathe, it’s essential to evaluate your specific needs.

| Criteria | Economic CNC Machine Tools | Standard CNC Machine Tools |

|---|---|---|

| Cost | Lower initial cost | Higher initial investment |

| Performance | Sufficient for basic tasks | Superior precision and speed |

| Maintenance | Often requires more upkeep | Generally lower maintenance |

| Durability | May wear out faster | Built for longevity |

In summary, while economic CNC Lathe might seem appealing due to their lower price, standard machines often provide better performance and durability, making them a more suitable choice for demanding projects.

How to choose the right CNC machine tools for your project

Selecting the appropriate CNC machine tools is essential for the success of any machining project. The choice can significantly impact efficiency, precision, and overall productivity. Here are the key considerations to guide your decision-making process.

Assess Your Machining Needs

The first step in choosing CNC Lathe is to assess your specific machining requirements. This involves understanding:

- Material Type: Different materials have unique properties that influence tool selection. For instance, harder materials like titanium require robust tools, often made from carbide or high-speed steel, to ensure efficient cutting.

- Complexity of Parts: The intricacy of the workpieces will dictate the type of tools needed. Complex geometries may require specialized tools with specific designs.

- Tolerance Levels: Higher precision demands tighter tolerances, necessitating high-quality tools that minimize runout and maintain accuracy.

Evaluate Tool Materials and Coatings

The material and coating of CNC tools play a crucial role in their performance and durability. Common materials include:

- High-Speed Steel (HSS): Ideal for general-purpose machining due to its toughness.

- Carbide: Offers superior hardness and wear resistance, making it suitable for high-speed applications.

- Ceramic Tools: Best for cutting hard materials but are more brittle.

Coatings like titanium nitride (TiN) enhance tool life by providing a harder surface that reduces friction and wear. Choosing the right combination of material and coating is vital for optimizing performance.

Consider Machine Specifications

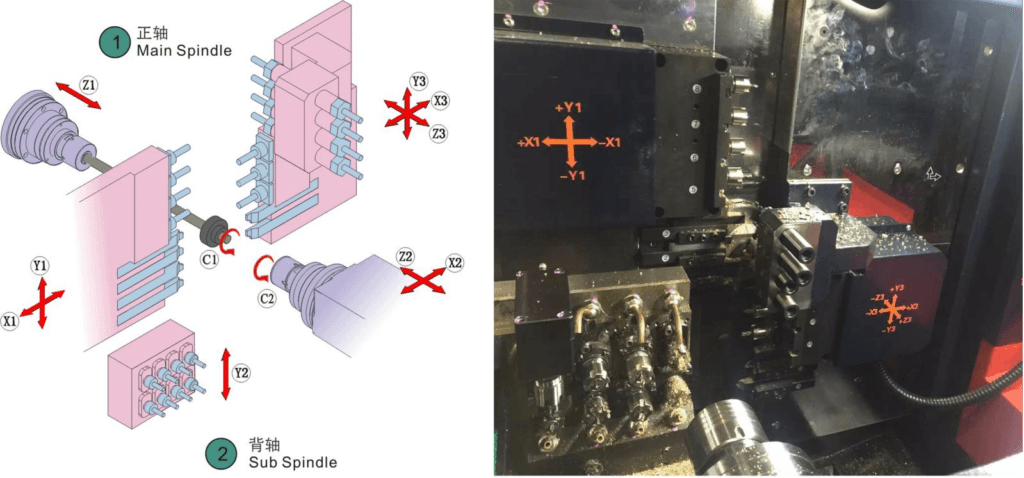

When selecting CNC machine tools, it’s essential to consider the specifications of your CNC machine itself:

- Power and Capacity: Ensure that the machine has sufficient power to handle the required cutting operations without overheating or stalling.

- Guide Ways: Decide between Linear Motion (LM) guide ways for speed or box guide ways for rigidity. The choice affects speed, load capacity, and tool life.

- Control Systems: Evaluate the CNC control system’s reliability, user-friendliness, and compatibility with your existing software. A robust control system can enhance operational efficiency and ease of use.

Cost Considerations

While cost is a significant factor in any purchasing decision, it should not be the sole determinant. Consider:

- Initial Investment vs. Long-Term Value: Cheaper tools may save money upfront but can lead to higher operational costs due to frequent replacements or maintenance needs.

- Return on Investment (ROI): Analyze how the chosen tools will impact productivity and quality over time to justify the investment.

Supplier Reliability and Support

Finally, consider the reputation of CNC Lathe manufacturers and suppliers. Reliable suppliers offer not only quality products but also essential support services such as maintenance, spare parts availability, and technical assistance. Building strong relationships with suppliers can lead to better pricing and support options.

Choosing the right CNC Lathe is not just about picking a name from a list; it requires careful consideration of various factors including manufacturers, market trends, economic costs, available space, and specific project requirements. By doing so, you can set your projects up for success!