In today’s manufacturing world, the CNC Machine has become an essential tool for boosting production efficiency and machining precision. Whether you’re making automotive parts, electronic components, or complex aerospace pieces, choosing the right CNC machine directly impacts your product quality and business competitiveness. For B2B clients, faced with a wide range of models and brands, how do you select the most suitable CNC machine based on your product requirements, budget, and production batch size? That’s the big question.

This article will guide you through the key factors to consider when purchasing a CNC machine, helping you clarify your needs and make smart decisions. Whether you’re running a small factory just starting out or a large manufacturer looking to scale up, you’ll find practical advice and insights here.

1. Clarify Your Product Requirements

The first step in choosing a CNC machine is to clearly understand your product requirements. Different industries have very different needs:

- Automotive: Usually requires high-precision, high-efficiency equipment for mass production of complex parts.

- Aerospace: Demands extremely high precision and complexity, often using five-axis machines for intricate surfaces.

- Electronics: Needs small, precise parts, typically favoring compact, high-precision CNC machines.

- Custom Parts Manufacturing: For small batches and multiple varieties, flexibility and fast tool changing are key.

Other factors to consider:

- Workpiece Size: Larger parts need bigger worktables and travel distances.

- Material Type: Metals, plastics, and composites all affect machine rigidity and tool selection.

- Machining Precision: High-precision work may require advanced control systems and stable mechanical structures.

Tip: When searching, try phrases like “CNC machine for automotive parts” or “precision CNC machining for electronics” to find better-matched equipment and solutions.

2. Budget Planning and Return on Investment

Buying a CNC machine isn’t as simple as just picking one off the shelf—budget is always a key concern. Prices for CNC machines vary widely, from tens of thousands to millions of RMB, depending on factors such as:

- Brand reputation

- Machine type and features

- Level of automation (such as robotic tool changers)

- Software and control systems

How should you plan your budget?

- Initial Purchase Cost: Choose a machine that meets your needs without unnecessary features to avoid overspending.

- Operating Costs: Electricity, labor, tooling, and consumables.

- Maintenance Expenses: Regular servicing and spare parts.

- Return on Investment: Efficient machines can shorten production cycles, reduce scrap rates, and increase overall profits.

For example, if you have large production batches, investing in a highly automated CNC machine may have a higher upfront cost, but it can significantly cut labor and downtime in the long run.

Recommended keywords: “affordable CNC machine for small business,” “cost-effective CNC machining solution.”

3. Consider Batch Size and Production Scale

The size of your production batches has a direct impact on your CNC machine choice:

- Small Batch, Multiple Varieties: Best suited for flexible machines with quick tool changes, such as compact machining centers or multifunctional CNC lathes.

- Large Batch, Single Variety: High automation and stability are key, enabling long periods of unattended operation.

| Production Batch Type | Machine Features | Typical Applications |

|---|---|---|

| Small Batch | Flexible tool change, quick setup | Custom parts, small batch runs |

| Large Batch | High automation, strong stability | Standardized mass production |

Flexible manufacturing systems can also help balance the needs of small batches and multiple varieties, improving efficiency.

Long-tail keywords: “CNC machine for small batch production,” “high-volume CNC machining center.”

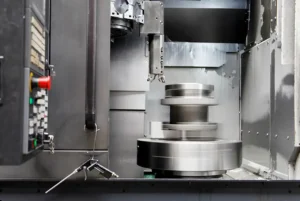

4. CNC Machine Types and Configuration Selection

There are many types of CNC machines on the market. Knowing the common types helps you narrow your choices quickly:

- CNC Lathes: Ideal for rotational parts such as shafts and sleeves.

- Machining Centers: Multi-axis, suitable for complex milling, drilling, and multi-process machining.

- Swiss-Type Lathes: Great for tiny, precise parts, often used in electronics and medical industries.

- Five-Axis Machines: Can control five axes simultaneously, perfect for complex surface machining.

Key parameters include:

- Number of axes (3-axis, 4-axis, 5-axis)

- Worktable size and travel range

- Spindle power and speed

- Control system compatibility (such as CAD/CAM support)

Also, pay attention to software usability and automation integration, like MES system compatibility.

Recommended keywords: “5-axis CNC machine for complex parts,” “Swiss type CNC lathe manufacturer.”

5. Workshop Space and Environmental Requirements

Don’t forget, machine size and your workshop environment matter too:

- Equipment Size: Make sure your workshop has enough space for the machine and operator movement.

- Ventilation and Dust Removal: Machining generates dust and debris that need to be handled promptly for safety.

- Safety Facilities: Protective covers and safety doors are essential for operator safety.

If space is limited, consider a compact CNC machine to save space without sacrificing capability.

Long-tail keywords: “compact CNC machine for limited space,” “CNC machine workshop setup.”

6. Brand and After-Sales Service

When buying a machine, service is just as important as the machine itself. Choosing a reputable brand ensures quality and reliability. More importantly:

- Technical Support: Fast response to solve equipment issues.

- Spare Parts Supply: Timely delivery of consumables to minimize downtime.

- Training Services: Help operators get up to speed quickly and use the machine efficiently.

- Maintenance: Regular inspections to extend machine life.

Check the supplier’s after-sales reputation to avoid being left unsupported.

Recommended keywords: “reliable CNC machine supplier,” “CNC machine after-sales support.”

Conclusion and Selection Process Recommendations

Choosing the right CNC machine means considering everything systematically:

- Product Requirements: Define your workpiece size, materials, and precision.

- Budget Planning: Allocate funds for purchase and operation wisely.

- Production Batch Size: Match machine flexibility and automation to your needs.

- Machine Type and Configuration: Choose equipment that fits your process.

- Workshop Environment: Ensure adequate space and safety.

- Brand and Service: Pick a supplier you can count on.

Remember, buying a CNC machine is an investment. We recommend assessing your actual needs and contacting our professional team for a customized solution. With years of experience in CNC machines, we’re ready to help you boost your production!

If you’re planning to upgrade or purchase a CNC machine, feel free to contact us for expert advice and a competitive quote. Let’s work together to build an efficient and precise manufacturing future!