The 3-axis CNC lathe isn’t just a machine-it’s the workhorse of modern manufacturing. From crafting precision aerospace components to mass-producing automotive parts, this tool combines speed, accuracy, and versatility like no other. Imagine turning a raw metal block into a complex turbine blade in minutes-this is the magic of 3-axis CNC lathe. In this deep dive, we’ll dissect every critical component, revealing how they work together to deliver results that manual machining simply can’t match.

Core Structural Components of a 3-Axis CNC Lathe

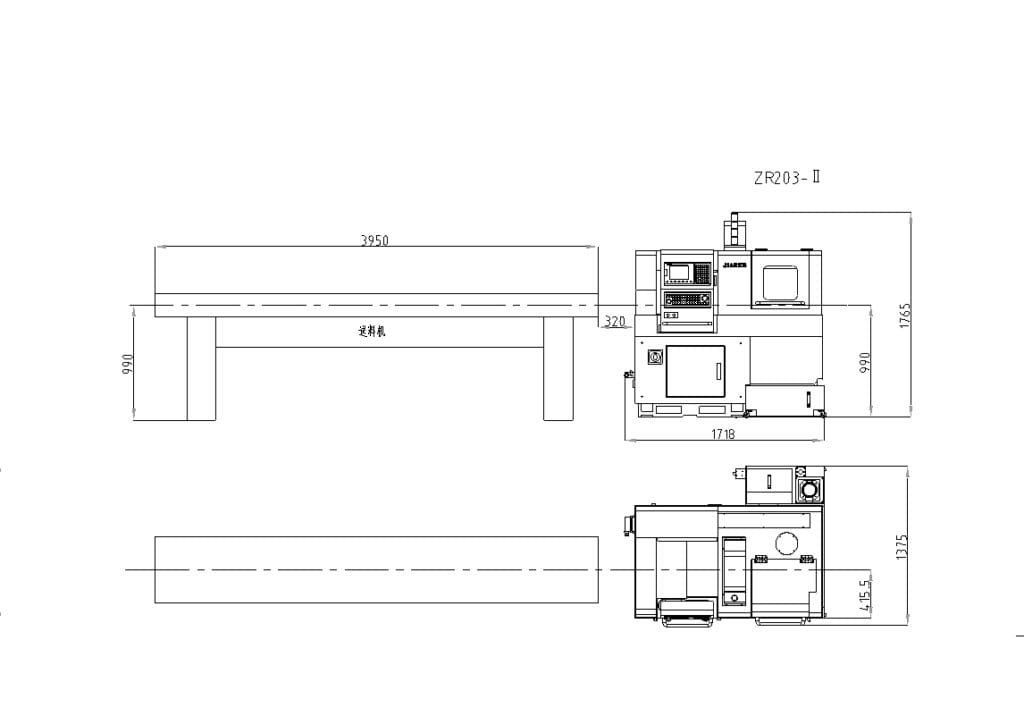

Overall Frame and Bed

Think of the bed as the lathe’s backbone. Made from high-grade cast iron or polymer-concrete composites, it absorbs vibrations like a shock absorber. For example, JiankeMach’s beds use patented ribbing designs, reducing thermal deformation by 15% compared to standard models (source: JiankeMach Technical Specifications).

Spindle System

The spindle is the lathe’s heart. High-torque motors (like 20kW AC servo drives) spin at 5,000 RPM, while hybrid ceramic bearings ensure longevity-perfect for non-stop production runs.

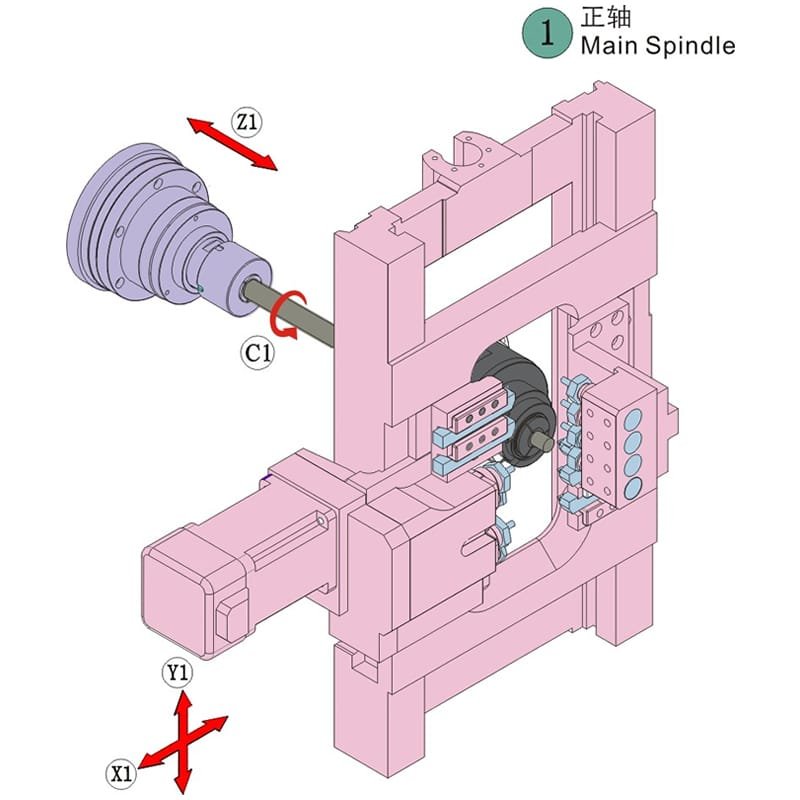

Feed System (X, Y, Z Axis Drives)

Precision here separates hobbyist machines from industrial giants. A 0.001mm resolution ball screw means you could mill a hair’s width with confidence.

Detailed Explanation of Main Components

Spindle Unit

- Spindle Motor: Opt for direct-drive motors to eliminate gear backlash-ideal for mirror-finish titanium parts.

- Spindle Bearings: Angular contact bearings handle radial and axial loads simultaneously, like a sprinter pivoting mid-race.

- Spindle Cooling System: Liquid-cooled spindles maintain ±1°C stability, preventing “thermal drift” that ruins tight tolerances.

Turret/Tool Post System

- Automatic Tool Changer: A 12-station turret swaps tools in 0.8 seconds-faster than a Formula 1 pit crew.

- Tool Positioning: HSK tool holders grip with 10x the force of standard collets, minimizing deflection during heavy cuts.

Servo Motors and Drive System

- Forget stepper motors-closed-loop servos with 21-bit encoders self-correct positioning errors in real time.

Guideways and Ball Screws

- Linear Guideways: Preloaded roller guides support 2-ton loads while sliding smoother than ice on Teflon.

- Ball Screws: Ground (not rolled) screws achieve C3-grade accuracy-essential for medical implant machining.

Control System

- CNC Controller: FANUC or Siemens systems parse G-code faster than a chess grandmaster plans moves.

- Operation Panel: Touchscreen interfaces with haptic feedback let operators “feel” their way through setups.

3-Axis CNC Lathe Auxiliary Systems and Functional Components

Lubrication System

Automatic oil-mist lubrication cuts bearing wear by 40%, slashing downtime (source: Machinery Lubrication Journal).

Cooling System

High-pressure coolant (70 bar) blasts chips away while cooling tools-like a firehose for metal shavings.

Chip Removal System

Auger conveyors dump chips directly into bins, keeping floors clean and reducing slip hazards.

Safety

Laser-curtain guards stop the spindle instantly if a hand ventures too close-no lost fingers here.

Functions and Advantages of Main Components

- Precision and Stability

High-quality main components ensure that the lathe maintains excellent machining accuracy and stability even under high speed and heavy loads. A well-tuned lathe holds ±0.005mm tolerances-half the thickness of a human hair. - Automation and High-Efficiency Production

Integrated systems such as automatic tool changers, lubrication, and chip removal significantly improve production efficiency and reduce manual intervention. - Versatile Machining Capability

Flexible structural design and a wide range of tool configurations enable the 3-axis CNC lathe to handle a variety of complex workpieces, offering strong adaptability.

Here’s the bottom line: every component in a 3-axis CNC lathe is a precision-engineered cog in a high-speed, high-stakes machine. Skimp on the ball screws, and your parts will be scrap. Ignore cooling, and your spindle cooks itself. But get it right? You’ll outpace competitors, nail ISO certifications, and win contracts you once thought impossible. Ready to upgrade? Start by auditing your spindle bearings and control software-two areas where small investments yield massive ROI.

If you want to know more about the structure, function or selection recommendations of 3-axis CNC lathe, you can click the article link below to obtain detailed product information to help you make a more scientific purchasing decision.