The meticulously engineered components inside Swiss machine tool are synonymous with precision and reliability in advanced manufacturing. Originally developed for the Swiss watchmaking industry, these machines have evolved into essential assets for sectors demanding intricate, high-accuracy components—think medical devices, aerospace connectors, automotive fuel injectors, and micro-electronics. The secret behind their reputation? It’s not just the machines, but the meticulously engineered parts inside them.

This article will guide you through the essential Swiss lathe components, their technical advantages, real-world applications, and the innovations driving their performance. Whether you’re a manufacturer, engineer, or procurement specialist, you’ll gain actionable insights to elevate your operations. If you’re ready to explore specific products or want to see our full Swiss lathe parts portfolio, visit our product page for detailed specifications and quick inquiry options.

Overview of Swiss Machine Tool

Definition and Historical Development

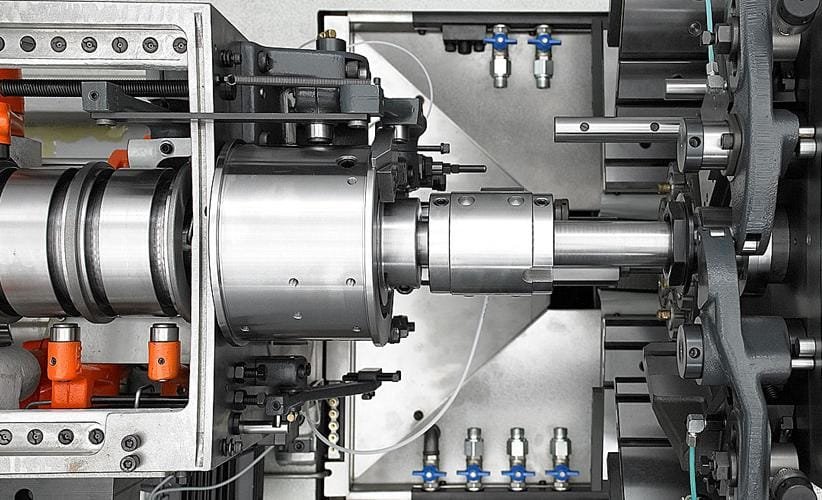

Swiss machine tools were born from the need for ultra-precise watch parts in Switzerland. Today, Swiss-type CNC lathes are the gold standard for mass-producing small, high-precision components, thanks to their unique sliding headstock and guide bushing design.

Structural Features

Unlike traditional lathes, Swiss-type lathes use a sliding headstock and guide bushing to support the workpiece close to the cutting tool. This design minimizes deflection and vibration, enabling tight tolerances and superior surface finishes—even on slender, delicate parts.

Main Types of Swiss machine tool Parts

The magic of Swiss lathes lies in the synergy of their specialized components. Let’s break down the most critical parts, with references for deeper exploration.

1. Guide Bushing

The guide bushing is the unsung hero of Swiss machining. It supports and precisely locates slender workpieces, allowing for aggressive cutting without deflection. This is why Swiss lathes can reliably produce parts with tolerances measured in microns—vital for medical implants and watch gears.

2. Sliding Headstock

The sliding headstock moves the workpiece axially while keeping it close to the cutting tool. This dynamic support system is what enables the machining of long, thin parts that would otherwise whip or bend under traditional methods.

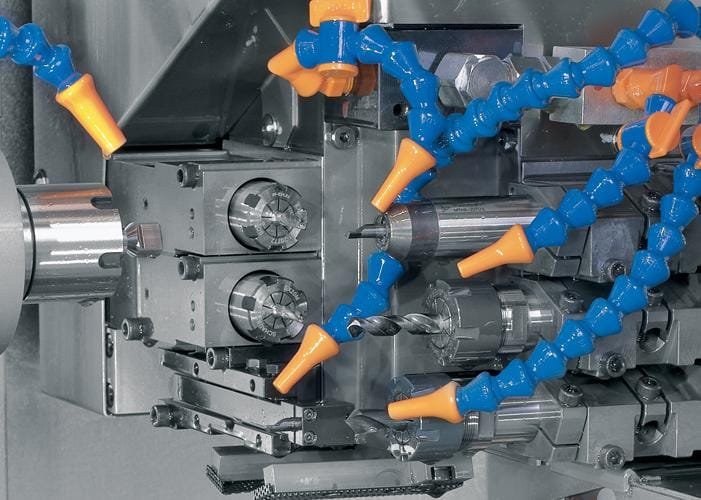

3. Multispindle System & Tool Turret

A multispindle system allows simultaneous machining of multiple workpieces, multiplying productivity. Tool turrets hold numerous tools and enable complex, multi-step operations in a single setup. For example, manufacturers can turn, mill, drill, and tap a medical bone screw without moving the part between machines—saving time and reducing errors.

4. Precision Collets & Hydraulic Chucks

Precision collets and hydraulic chucks grip small or oddly shaped workpieces with repeatable accuracy. Hydraulic chucks, in particular, speed up tool changes and improve clamping consistency—critical for high-mix, low-volume production runs.

5. Bar Feeder

Bar feeders automate the supply of raw material, enabling lights-out manufacturing. This means the machine can run unattended for hours or even overnight, maximizing spindle utilization and lowering labor costs.

6. High Pressure Coolant System

High-pressure coolant systems deliver coolant directly to the cutting zone at pressures up to 2000 psi, extending tool life, improving chip evacuation, and enabling faster cutting speeds—especially with tough materials like titanium or stainless steel.

Technical Advantages of Swiss Lathe Parts

Micron-Level Precision and Repeatability

Swiss lathes routinely achieve tolerances within ±2 microns, making them indispensable for industries where failure isn’t an option—such as surgical devices or aerospace fasteners.

All-in-One Machining

With multi-axis capability and tool turrets, Swiss lathes perform turning, milling, drilling, and tapping in a single setup. This reduces handling, shortens lead times, and slashes the risk of dimensional errors.

Unmatched Automation and Productivity

Automatic bar feeders and programmable tool changes enable continuous, unattended operation. Shops can run “lights out,” boosting output and reducing costs.

Superior Surface Finishes

The close support of the guide bushing and optimized coolant delivery result in mirror-like surface finishes, minimizing or eliminating secondary polishing.

Typical Application Fields of Swiss Lathe Parts

Medical Devices

Swiss lathes are the go-to for orthopedic implants, dental abutments, and micro screws, where flawless geometry and biocompatibility are non-negotiable.

Aerospace

They machine lightweight, high-strength connectors and sensor housings, where every gram and micron counts.

Automotive Industry

Used for precision fuel injectors, valve bodies, and transmission components that must withstand extreme conditions.

Electronics & Communications

Ideal for micro connectors, pins, and RF components—parts that power the world’s smartphones and satellites.

Watches & Precision Instruments

The original application: producing tiny gears, shafts, and levers for luxury timepieces and scientific instruments.

If your business operates in any of these sectors and you’re seeking to upgrade your production capabilities, browse our product Dual spindle centering machine or reach out for tailored recommendations.

Manufacturing Processes and Innovations in Swiss Lathe Parts

- Blending Skilled Craftsmanship with Automation

While automation drives efficiency, experienced machinists fine-tune processes for optimal results—especially for prototype or high-value parts. - Multi-Axis CNC and Industry 4.0 Integration

Modern Swiss lathes feature up to 12 axes and are often connected to digital monitoring systems, enabling real-time quality control and predictive maintenance. - Advanced Materials and Surface Treatments

Manufacturers use specialty alloys and high-performance coatings to enhance durability, corrosion resistance, and biocompatibility. - Rigorous Quality Control

Every part is inspected using coordinate measuring machines (CMMs), laser micrometers, or optical systems, ensuring compliance with the strictest standards—such as ISO 13485 for medical devices.

Key Factors for Choosing a Quality Swiss Lathe Parts Supplier

- Technical Depth and Innovation

Look for suppliers with a proven track record of process innovation and the ability to tackle complex, custom projects. - Industry-Specific Experience

A supplier with case studies in your sector understands your challenges and can offer tailored solutions. - Responsive Support and Service

Fast, knowledgeable support keeps your machines running and minimizes costly downtime. - Certifications and Traceability

Insist on ISO or industry-specific certifications, and demand full traceability for every part—especially in regulated industries.

Swiss machine tool parts are the backbone of modern precision manufacturing, enabling breakthroughs in medicine, aerospace, automotive, and beyond. By investing in high-quality Swiss lathe components, you’re not just upgrading your machines—you’re future-proofing your business. As digital manufacturing and automation advance, Swiss lathe technology will only become more vital, opening new possibilities for innovation and growth.

Don’t miss your chance to stay ahead explore our latest Swiss lathe parts, or get in touch admin@jiankemach.com for a custom quote and expert guidance tailored to your needs.