In modern manufacturing, CNC lathe have become indispensable production tools. With continuous technological advancements, multi-axis CNC lathe are now widely used, helping businesses achieve higher machining accuracy and efficiency. As a professional CNC lathe manufacturer, we understand the differences in performance and applications between CNC lathes with different numbers of axes. Today, we’ll guide you through the distinctions among 3-axis, 5-axis, 6-axis, and 9-axis CNC lathe, helping you make informed decisions when purchasing equipment.

Whether you’re just starting to learn about CNC lathes or looking to upgrade your existing equipment, this article will provide you with clear and practical insights. Ready to unlock the secrets of multi-axis CNC lathes? Let’s dive in!

CNC Lathe Axis Basics

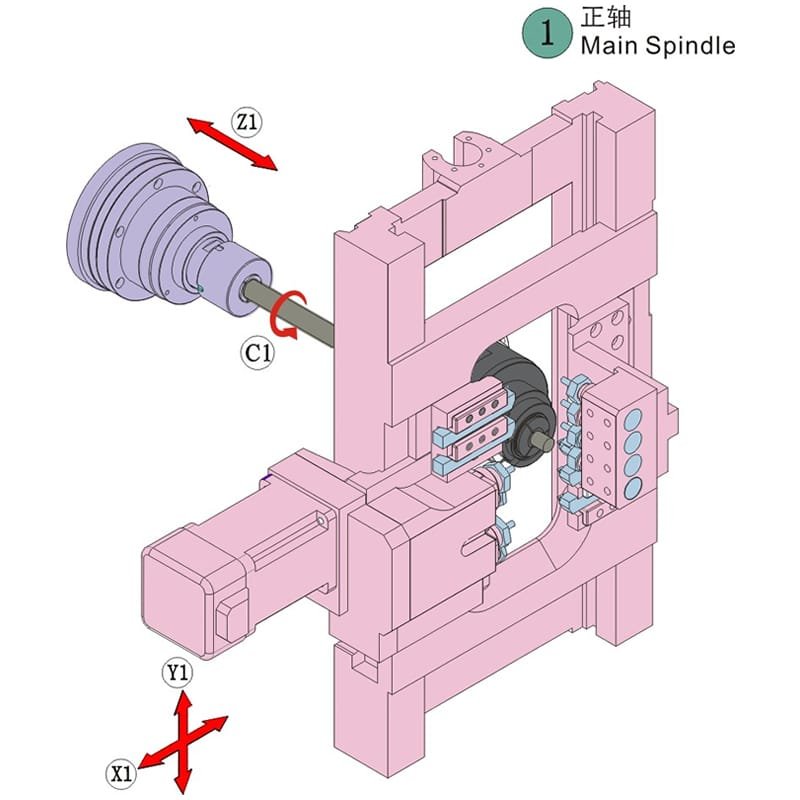

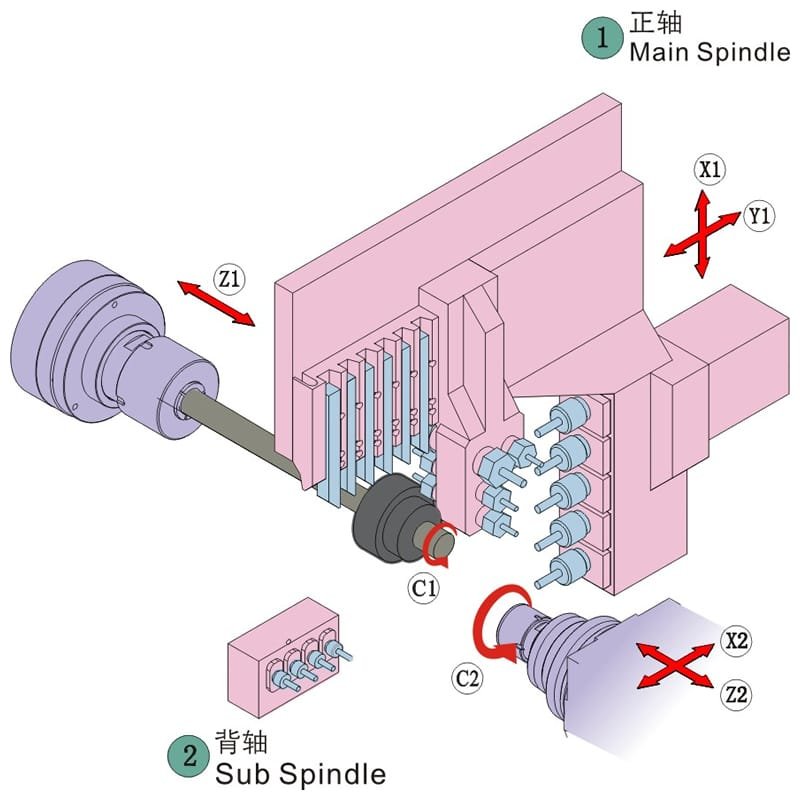

First, what exactly is an “axis”? Simply put, an axis refers to a direction in which the machine can move or rotate. The most common are the X, Y, and Z linear axes, which correspond to left-right, front-back, and up-down movements. In addition, there are rotary axes, such as the A, B, and C axes, representing rotations around different directions.

The more axes a machine has, the greater its freedom of movement, allowing it to handle more complex machining tasks. In other words, the number of axes directly impacts a CNC lathe’s machining capability and flexibility.

3-Axis CNC Lathes

3-axis CNC lathes are the most basic models, equipped with X, Y, and Z linear axes. They are primarily used for turning and simple milling operations.

Typical Applications:

- Machining simple cylindrical parts

- Standard batch production

- Manufacturing low-complexity products

Advantages:

- Easy programming and operation

- Lower equipment and maintenance costs

- Suitable for general part machining

Limitations:

- Cannot complete multi-face machining in one setup

- Limited capability for complex surfaces and deep cavities

- Requires multiple setups, affecting efficiency and accuracy

In short, a 3-axis CNC lathe is like the basic blade of a Swiss Army knife-practical but limited in function.

5-Axis CNC Lathes

A 5-axis CNC lathe adds two rotary axes (usually A and C axes) to the basic three, allowing the tool to approach the workpiece from different angles.

Enhanced Machining Capabilities:

- Can machine complex surfaces and inclined planes

- Enables multi-face machining in a single setup

- Ideal for mold making, aerospace parts, and medical devices

Main Advantages:

- Greatly improves machining efficiency by reducing tool changes and setups

- Enhances machining accuracy and reduces human error

- Supports the production of parts with complex geometries

Typical Industry Examples:

- Complex surface machining for aerospace components

- Automotive engine part manufacturing

- High-end medical device components

Imagine a 5-axis CNC lathe as a Swiss Army knife with added tools, ready to tackle more challenging tasks.

6-Axis CNC Lathes

6-axis CNC lathes typically add an extra rotary or feed axis to the 5-axis configuration, further boosting machining flexibility.

Features:

- Supports even more complex part machining

- Suitable for automated production lines and integration with robots

- Increases production efficiency and shortens delivery times

Application Scenarios:

- Batch production of highly complex parts

- Automated manufacturing requiring multiple linked processes

- Precision mechanical and electronic component machining

A 6-axis machine is like the premium version of a Swiss Army knife-more versatile and efficient, meeting even stricter machining requirements.

9-Axis CNC Lathes

9-axis CNC lathes are among the most advanced machines on the market, integrating both turning and milling functions with multiple rotary and feed axes.

Advantages:

- Completes all machining processes for extremely complex parts in a single setup

- Delivers exceptionally high machining accuracy and surface quality

- Greatly reduces manual intervention and secondary operations

Application Fields:

- High-end aerospace components

- Medical implants and precision instruments

- Complex molds and high-precision mechanical parts

You could say a 9-axis CNC lathe is the “superhero” of manufacturing, enabling businesses to achieve the ultimate in machining performance.

Comparison Table: Different Axis CNC Lathe

| Axes | Structural Features | Machining Capability | Application Scenarios | Advantages | Limitations |

|---|---|---|---|---|---|

| 3 | X/Y/Z linear axes | Simple/general parts | General part machining | Easy programming, low cost | Multiple setups for complex parts |

| 5 | X/Y/Z + 2 rotary axes | Complex surfaces/multi-face | Molds, aerospace, medical | Single setup, high efficiency | Complex programming, higher cost |

| 6 | 5-axis + 1 additional axis | Higher complexity parts | Automated production lines | Greater flexibility, high efficiency | Higher equipment investment |

| 9 | Turning-milling + multi-axis | Extremely complex precision parts | High-end precision manufacturing | One-pass machining, ultra-high precision | High technical threshold, high cost |

How Customers Should Choose the Right CNC Lathe

Choosing the right number of axes for your CNC lathe depends on your actual needs:

- Product Complexity

- For simple parts, a 3-axis lathe is sufficient

- For complex surfaces and multi-face machining, consider 5-axis or above

- Machining Accuracy Requirements

- For high-precision products, 5-axis or 6-axis is recommended

- For ultra-high precision and complex processes, opt for 9-axis

- Production Volume and Efficiency

- For mass production and high automation needs, 6-axis is more suitable

- For small batches and diverse products, 3-axis or 5-axis offers more flexibility

- Budget and ROI

- Balance equipment and maintenance costs

- Remember, improved equipment performance can lead to higher efficiency and quality, often resulting in greater returns

Tip: Unsure which machine to choose? Contact us! Our expert team will provide tailor-made solutions based on your specific requirements.

Choosing the right CNC lathe is more than just buying a machine-it’s an investment in your company’s future productivity and competitiveness. Whether it’s 3-axis, 5-axis, 6-axis, or 9-axis, each type has its unique advantages and application scenarios. Understanding these differences will help you match your production needs precisely and improve both efficiency and product quality.

If you’re looking for high-quality, multi-axis CNC lathes or want to learn more about equipment configurations and custom solutions, please feel free to contact us. Let’s work together to take your manufacturing business to new heights of intelligence and efficiency!

We look forward to your inquiries and cooperation! Let’s build a brighter manufacturing future together!