CNC milling and turning support high-precision manufacturing in the rapid development of modern production. Whether you need to prototype a single aerospace component or operate a large-scale auto parts production line, CNC milling and turning can meet your needs.

But what makes them different? How do they work together to create complex geometries?

This article will analyze CNC milling and turning in depth to help you master the core of precision manufacturing.

What is CNC Milling and Turning?

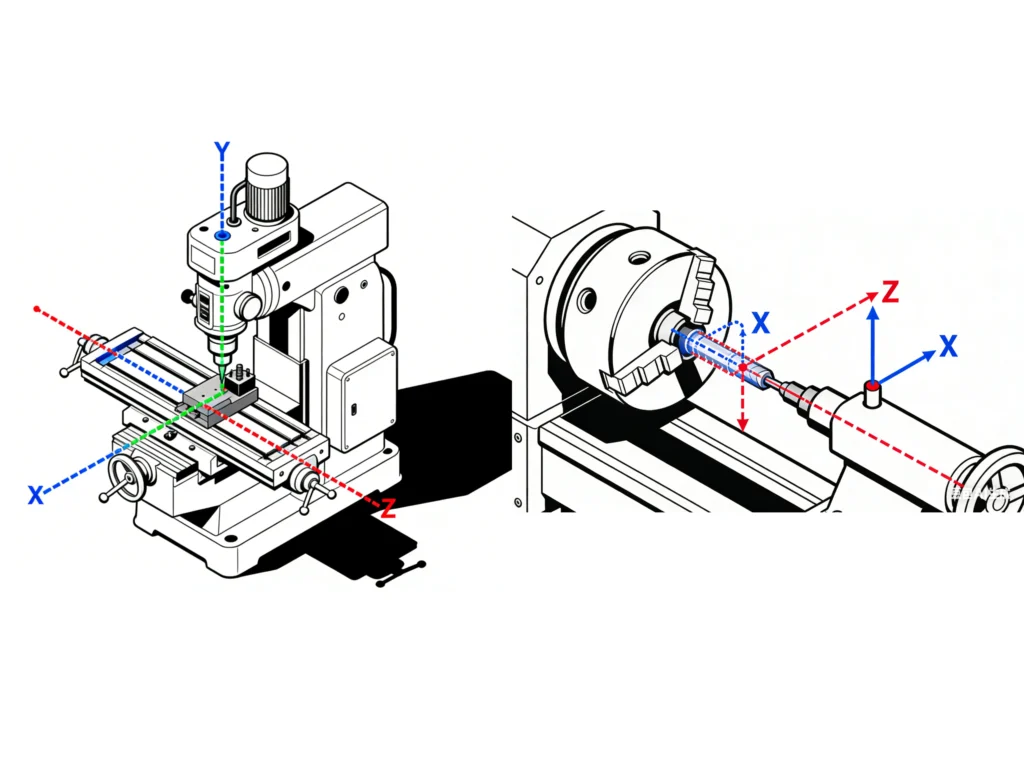

Computer Numerical Control (CNC) automates the control of machine tool tools through a sequence of software programming. However, there are significant differences in mechanical principles between milling and turning.

Defining CNC Milling

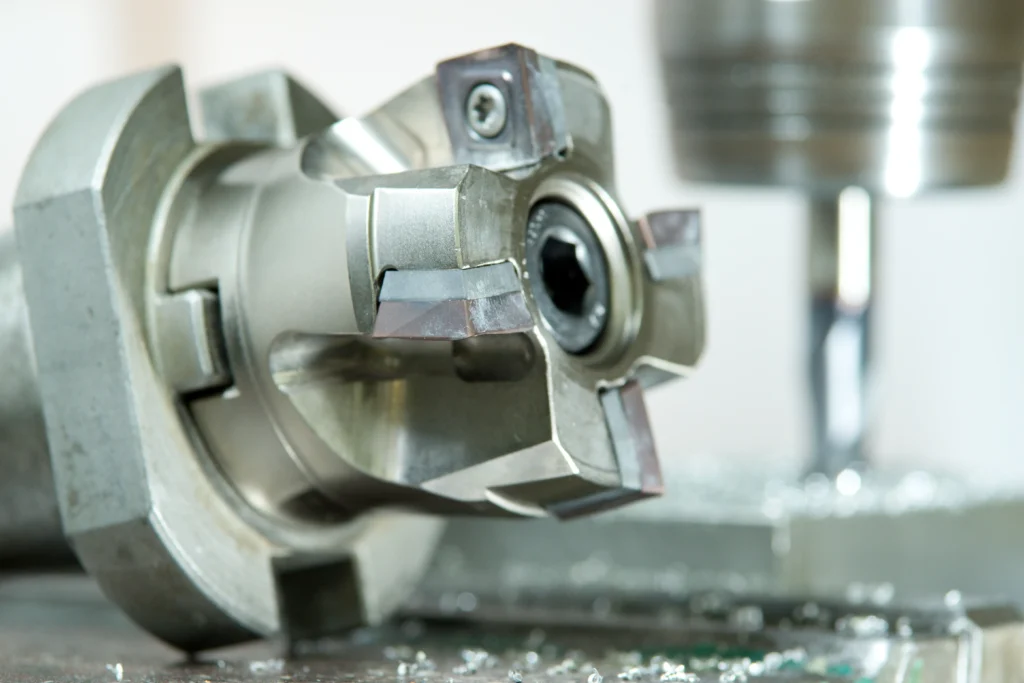

CNC milling is a process that uses a high-speed rotating cutting tool to remove material from a workpiece that remains stationary (or moves along a specific axis). It is the preferred method for manufacturing non-cylindrical parts and their complex features such as grooves, holes and cavities.

Defining CNC Turning

In contrast, CNC turning involves high-speed rotating workpieces, while stationary cutting tools move linearly to ‘scrape’ materials. The process is mainly used to manufacture cylindrical or tubular parts such as shafts, bushings and bolts.

When the two are combined, CNC milling and turning meet the vast majority of machining needs of modern engineering.

CNC Milling vs. Turning: What is the Difference?

The difference between the two is usually attributed to ‘what is moving?’. The following table clearly shows the specific differences:

| Table: Difference Between CNC Milling & Turning | ||

|---|---|---|

| Feature | CNC Milling | CNC Turning |

| Workpiece Motion | Stationary (fixed to a bed) | Rotates (held in a chuck) |

| Tool Motion | Rotates and moves on X, Y, Z axes | Stationary (moves linearly) |

| Primary Shape | Square, flat, or complex 3D shapes | Cylindrical, round, or tubular |

| Cutting Action | Multi-point cutting tools | Single-point cutting tools |

| Typical Parts | Engine blocks, gears, brackets | Shafts, knobs, pulleys |

JIANKE Mechanical Note: If you want to know which process is more affordable? The answer depends on the geometry. For circular parts, turning is usually faster and cheaper; for non-rotating complex structures, milling is necessary.

How Does the Process Work?

CNC milling and turning follow a similar ‘digital to physical’ workflow. This structured approach ensures that the final product meets strict tolerance requirements.

CAD Design : Engineers use computer-aided design (CAD) software to create 3D models.

CAM Conversion: computer-aided manufacturing (CAM) software converts 3D models into G-code (a language that machines can understand).

Machine Setup: The operator loads raw materials (blanks) and selects the appropriate tool.

Machining: The machine executes G code and automatically performs CNC milling and turning operations.

Quality Control: Use three coordinate measuring machines (CMM) to check parts to ensure accuracy.

If you want to know how to set the machine, you can browse the relevant articles – CNC Lathe Setup Guide : Master Tool Offsets & Work Zero Fast

Why Use Mill-Turn Centers?

With the advancement of technology, the boundary between these two processes becomes blurred. This introduces the Mill-Turn Center.

What is a Mill-Turn Center?

The mill-turn center is a hybrid machine tool that combines two capabilities. It can either rotate the workpiece for turning operation, or it can be locked in place using a rotating tool for milling.

Advantages of Hybrid Processing:

- Reduce Clamping Time: No need to move parts from the lathe to the milling machine.

- Higher Accuracy: Fewer clamping times means less chance of alignment error.

- Complicated Geometry: Ideal for parts that are primarily cylindrical but require planar features or eccentric holes.

For complex projects, the use of machining shops that provide integrated CNC milling and turning capabilities is often the most efficient way.

Common Materials for CNC Milling and Turning

One of the biggest advantages of CNC machining is the diversity of materials. They can handle a wide range of raw materials.

Metals

Aluminium (6061, 7075): This is known for its light weight, easy processing and corrosion resistance. It is an ideal choice for aerospace and consumer electronics.

Stainless Steel (303,304,316): High strength and heat resistance. It is commonly used in medical and automotive fields.

Brass and Copper: Excellent electrical conductivity and low friction coefficient.

Plastics

Delrin/POM: High stiffness and low friction, ideal for precision gears.

PEEK: A high-performance plastic that is used in medical implants due to its biocompatibility.

Key Applications in Industry

The versatility of CNC milling and turning provides power for a number of key industries:

- Aerospace: The manufacture of turbine blades (milling) and landing gear components (turning) requires very strict tolerances to ensure safety.

- Medical: Surgical instruments and bone screws rely on the precision of Swiss type lathe.

- Automotive: From engine pistons to custom dashboard panels, machining is essential for prototyping and mass production.

- Electronics: Radiators and enclosures are usually manufactured by milling to protect sensitive internal components.

Choosing the Right Manufacturer

When purchasing a CNC machine, you need to choose a professional partner who understands the nuances of CNC milling and turning. Searching for suppliers with ISO 9001 and other certifications ensures a strict quality management system.

In addition, the supplier’s capacity should also be considered. Do they have a 5-axis lathe machine for complex contours? Does their lathe provide Live Tooling?

For more detailed specifications on standard machining tolerances and guides, resources like Thomas Net’s Machining Guide provide an excellent industry benchmark.

Conclusion

The key to mastering CNC milling and turning is to understand the advantages of each process. By using these technologies – whether used alone or in hybrid mill-turn centers – manufacturers can achieve unsurpassed accuracy and scalability. Whether you are an engineer designing the next breakthrough product or a purchasing manager purchasing parts, you realize that the synergy between milling and turning is the key to successful manufacturing.

Are you looking to optimize your next project? [Contact our JIANKE Mechanical Team] to discuss how our advanced CNC lathe makes your design a reality.