Have you ever wondered why CNC machine structures vary so much in the market? Especially when it comes to double rotary table (B+C axis) and single rotary table designs—what’s the real difference? For those in manufacturing, choosing the right CNC machine structure not only affects machining efficiency but also directly impacts product quality and cost control.

In this article, we’ll dive deep into the differences between double rotary table and single rotary table structures. We’ll clarify their pros and cons and explore which applications suit each design. Whether you’re a mold maker, an automotive parts manufacturer, or an aerospace expert, you’ll find practical insights here. Let’s demystify CNC 5-axis machine structures together and help you make the best choice for your business.

CNC Machine Five-Axis Structure Basics

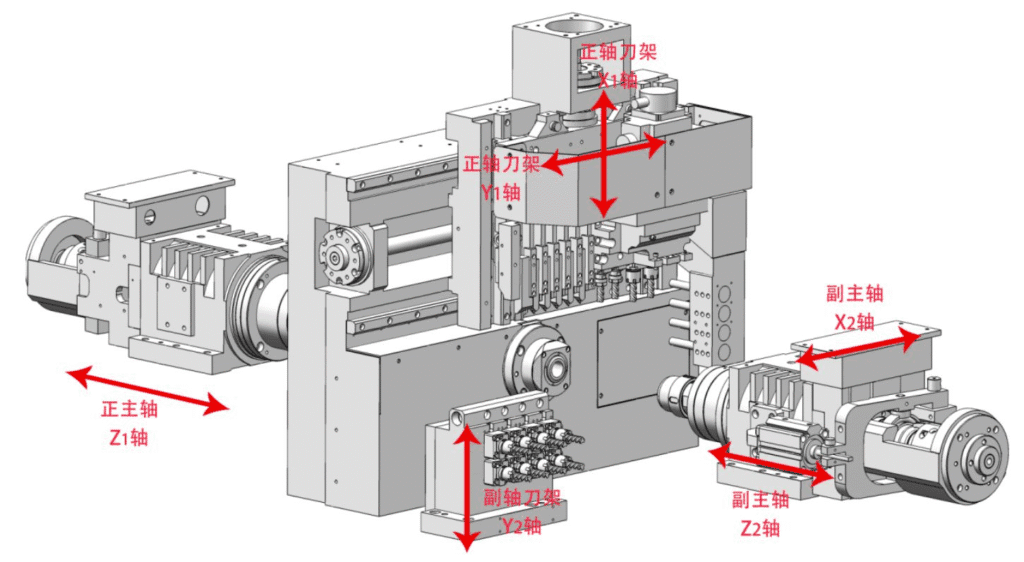

Before we compare, it’s important to understand the basics of five-axis CNC machines. A five-axis CNC machine can move in five different directions at the same time, greatly improving flexibility and precision.

- Three basic axes: X, Y, and Z control linear movement.

- B axis: Rotates around the X-axis, usually as a rotary table or tilting head.

- C axis: Rotates around the Z-axis, typically as a rotary table.

Different combinations of these axes define the machine’s capabilities and suitable uses. The double rotary table structure features both B and C axes as rotary tables, while the single rotary table usually has only one rotary table, with the other axis as a tilting head or similar.

Double Rotary Table Structure (B+C Axis) Explained

A CNC machine with a double rotary table structure is equipped with two rotary tables: B and C axes. This setup allows the workpiece to be positioned flexibly on two rotational axes.

Key Features:

- Strong spindle rigidity: The workpiece is fixed on the rotary table, reducing load on the spindle and making it ideal for heavy cutting.

- High machining precision: The double rotary table design minimizes workpiece movement errors, perfect for complex surface machining.

- Limited workpiece weight: Due to table size and load limits, this structure is best for small or medium-sized workpieces.

- Excellent for complex surfaces: Ideal for parts like turbine blades and precision molds.

Typical Applications:

- Aerospace engine blade manufacturing

- Automotive engine small parts

- Precision mold production

Although this structure comes with a higher cost, it offers strong support for high-precision and complex machining.

Single Rotary Table Structure Explained

In contrast, a single rotary table CNC machine features only one rotary table (usually the C axis), with the other axis (such as B) often being a tilting head.

Key Features:

- Simple structure: The design is more compact and easier to maintain.

- High flexibility: The spindle and rotary table work together for multi-face machining.

- Greater workpiece weight: Suitable for medium-sized and heavier workpieces.

- Wide machining range: Great for diverse part manufacturing.

Typical Applications:

- Mold making

- Aerospace components

- Multi-face automotive parts machining

Single rotary table machines are more cost-effective and easier to maintain, fitting a wide range of machining needs.

Double Rotary Table vs. Single Rotary Table: A Comparison

| Comparison | Double Rotary Table (B+C Axis) | Single Rotary Table |

|---|---|---|

| Spindle Rigidity | Higher, suitable for heavy cutting | Slightly lower, good for precision machining |

| Workpiece Weight | Lower, for small workpieces | Higher, for medium/large workpieces |

| Machining Flexibility | High, ideal for complex surfaces and angles | Good, suitable for multi-face machining |

| Structure Complexity | Higher, more challenging to maintain | Simpler, easier to maintain |

| Application | Small, precision parts | Medium-sized, diverse parts |

| Cost | Higher | Lower |

This table clearly highlights the core differences between the two structures. The right choice depends on your workpiece type and machining needs.

How to Choose the Right CNC Machine Structure?

Choosing the right CNC machine structure comes down to understanding your machining requirements:

- Workpiece Size and Weight

- Double rotary table is better for small, lightweight parts.

- Single rotary table suits medium to large workpieces.

- Machining Precision and Complexity

- For high precision and complex surfaces, double rotary table is ideal.

- For multi-face machining and flexibility, single rotary table excels.

- Budget and Maintenance

- Double rotary table costs more and is harder to maintain.

- Single rotary table is more economical and easier to service.

- Industry Application

- Aerospace and precision mold makers often prefer double rotary table.

- Automotive and general machinery manufacturers commonly choose single rotary table.

In summary, both double rotary table (B+C axis) and single rotary table structures have their strengths. If your factory focuses on high-precision, complex, small-part machining, the double rotary table is your best bet. It delivers higher machining accuracy and stronger spindle rigidity, meeting strict manufacturing requirements.

However, if your business covers a broader range, with varying workpiece sizes and a need to reduce maintenance costs, the single rotary table is a better fit. Its flexibility and cost-effectiveness help you handle diverse machining tasks with ease.

No matter your industry, choosing the right CNC machine structure can significantly boost productivity and product quality. Want to learn more about CNC five-axis machine structures or need a customized solution? Contact us anytime. Let’s work together to achieve efficiency and precision in your manufacturing!

FAQ

Mainly small, lightweight, and complex parts like turbine blades and precision molds.

Yes, single rotary tables usually support heavier, medium to large workpieces.

Single rotary table machines are generally simpler and easier to maintain.