Understanding CNC Technology

CNC, or Computer Numerical Control, refers to the use of computerized systems to control machine tools. Unlike traditional manual machining, where operators physically guide tools, CNC automates the process using pre-programmed instructions. This technology allows for precise control over cutting, drilling, milling, and other machining operations.

Key Advantages of Computer Numerical Control:

- High Precision: CNC machines can achieve tolerances within microns, ensuring every component is identical to its design specifications.

- Flexibility: They can handle a wide range of materials—from metals like aluminum and stainless steel to plastics—making them versatile for various applications.

- Efficiency: Automation reduces production time while minimizing errors caused by human intervention.

For instance, consider the intricate fan blades in air conditioners. These blades must be perfectly balanced to ensure energy efficiency and quiet operation. Computer Numerical Control machines excel at producing such components with exacting precision.

How CNC Works

CNC technology operates through a systematic process that ensures accuracy and repeatability:

- Programming: Engineers design a component using CAD (Computer-Aided Design) software. The design is then converted into G-code—a machine-readable language—using CAM (Computer-Aided Manufacturing) software.

- Input and Setup: The G-code is loaded into the CNC machine’s controller. Operators secure the raw material on the machine bed and select appropriate tools.

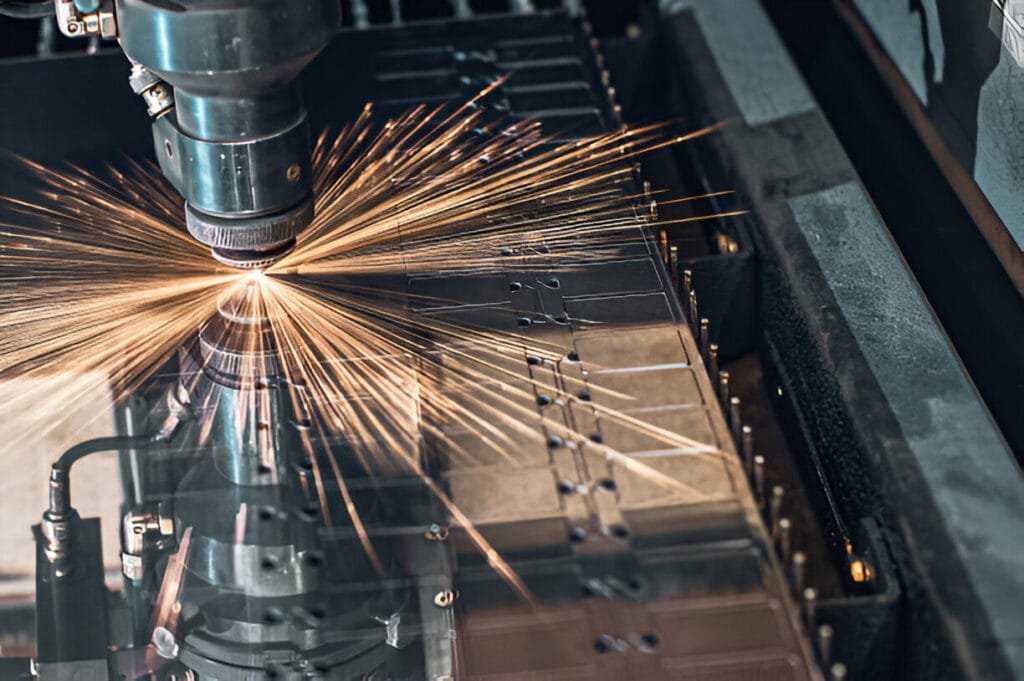

- Machining Process: The machine executes operations such as cutting, drilling, milling, or turning based on the programmed instructions. Multi-axis Computer Numerical Control systems (e.g., 3-axis or 5-axis) allow for complex geometries.

- Monitoring and Feedback: Sensors continuously monitor the process for deviations and provide real-time feedback to maintain precision.

Think of Computer Numerical Control as a highly skilled craftsman who never tires, never errs, and works at lightning speed—all while following instructions to the letter.

The Importance of CNC in Home Appliance Manufacturing

CNC technology is indispensable in home appliance manufacturing due to its ability to deliver high-quality components efficiently. Here’s why it matters:

1. Enhanced Production Efficiency

CNC machines operate 24/7 with minimal downtime, significantly increasing production capacity. For example:

- In washing machine production, CNC machines can cut and shape metal drums in minutes rather than hours.

- Automated tool changes allow manufacturers to switch between tasks seamlessly without halting production lines.

By reducing cycle times and eliminating bottlenecks, CNC ensures faster time-to-market for new products.

2. Precision for Complex Components

Modern appliances often feature intricate designs that require tight tolerances. For instance:

- Refrigerator compressors demand precisely machined parts to maintain optimal cooling performance.

- Microwave ovens rely on accurately fabricated waveguide components for efficient energy transfer.

CNC machines excel at producing such critical parts with consistency across large volumes.

3. Customization Capabilities

Today’s consumers crave personalized products—whether it’s a refrigerator with a unique finish or a dishwasher tailored to fit compact spaces. Computer Numerical Control machines enable manufacturers to quickly adapt designs and produce customized components without extensive retooling.

4. Cost Optimization

While Computer Numerical Control equipment requires significant upfront investment, it delivers long-term cost savings by:

- Reducing material waste through precise machining.

- Minimizing defects that lead to costly rework or scrap.

- Lowering labor costs by automating repetitive tasks.

Applications of CNC in Home Appliance Manufacturing

1. Structural Components

CNC machines are widely used to fabricate external casings and internal structural parts for appliances such as refrigerators, washing machines, and ovens. Their ability to handle both metal sheets and plastic materials ensures durability while maintaining sleek aesthetics.

2. Critical Functional Parts

Key components like motors, compressors, fan blades, and heat exchangers require high precision for optimal performance. For example:

- Fan blades in air conditioners must be perfectly balanced to reduce noise and improve energy efficiency.

- Heat exchangers in refrigerators rely on finely machined grooves for effective thermal conductivity.

3. Mold Making

Injection molding is a common process for producing plastic parts in appliances like blender jars or microwave buttons. CNC machines play a crucial role in creating high-precision molds used in mass production.

4. Prototyping

During product development phases, manufacturers use CNC technology for rapid prototyping of new designs. This allows them to test concepts quickly and refine them before committing to full-scale production—a critical step in innovation cycles.

CNC technology has revolutionized the home appliance manufacturing industry by enabling precise, efficient, and cost-effective production processes. Its ability to produce complex components with high accuracy makes it an essential tool for modern manufacturers striving to meet consumer demands for quality and innovation.

As the industry embraces trends like smart manufacturing and sustainable production practices, Computer Numerical Control will play an even greater role in driving automation and competitiveness. By adopting this technology strategically, manufacturers can unlock new opportunities for growth while delivering exceptional value to their customers.

FAQ

1. What is CNC, and why is it important in home appliance manufacturing?

Computer Numerical Control is a technology that uses computers to control machine tools for precise manufacturing. It is vital in home appliance production because it ensures high precision, consistency, and efficiency, enabling manufacturers to produce durable and reliable components for appliances like refrigerators, washing machines, and dishwashers.

2. What types of appliances are made using CNC technology?

CNC technology is used to manufacture parts for various appliances, including washing machines, dryers, refrigerators, air conditioners, and dishwashers. Components like motor housings, compressor parts, fan blades, and structural casings are commonly produced using CNC.

3. How does CNC improve the quality of home appliances?

CNC ensures that every part is manufactured with exact specifications and minimal variation. This precision results in higher-quality appliances that are more durable, efficient, and reliable over time.

4. Can CNC machines produce customized appliance components?

Yes, CNC machines can easily adapt to produce customized components. By modifying the digital design and programming, manufacturers can create unique parts tailored to specific customer requirements without extensive retooling.

5. What materials can CNC machines work with in home appliance manufacturing?

CNC machines can handle a wide range of materials used in appliances, including metals (aluminum, stainless steel), plastics (ABS, polypropylene), and composites. This versatility allows manufacturers to choose the best material for each component.