What is CNC Automation?

CNC automation (Computer Numerical Control Automation) uses computer systems to control machines like CNC tools, automating tasks that once required manual effort. Instead of manually loading materials, adjusting settings, and monitoring processes, operators now rely on pre-programmed instructions (like G-code) to handle everything from cutting to drilling with incredible precision.

Think of CNC automation as turning machines into “tireless workers” that can run 24/7 without losing consistency. For example, robotic arms can load raw materials, transfer parts between machines, or even inspect finished products—all without human intervention. This ensures faster production and fewer errors.

Beyond physical tasks, CNC automation also manages data. Advanced systems track progress in real time, optimize schedules, and even predict maintenance needs. Some companies use IoT (Internet of Things) to connect machines for live monitoring and smarter decision-making.

In short, CNC automation isn’t just about running machines—it’s about creating smarter, faster, and more efficient production systems that save time and money while improving quality.

Advantages of CNC automation

CNC automation is reshaping the manufacturing landscape by delivering unmatched efficiency, precision, and scalability. Imagine a factory floor where machines work tirelessly around the clock—automated CNC systems can operate 24/7, dramatically increasing production output while eliminating the limitations of human fatigue. According to a Deloitte study, manufacturers implementing automation have reported productivity gains of up to 47%, making this technology indispensable for industries like aerospace, automotive, and medical device manufacturing.

Precision is another hallmark of CNC automation. Automated systems achieve tolerances as tight as ±0.001 inches, which is critical for creating components that must fit perfectly in complex assemblies like engines or medical implants. This level of accuracy reduces material waste, minimizes costly rework, and ensures consistent product quality—key factors in maintaining a competitive edge.

Automation also tackles one of the biggest challenges in manufacturing: human error. By reducing manual intervention, CNC automation lowers defect rates and improves workplace safety by keeping workers away from hazardous tasks such as handling sharp tools or operating heavy machinery. While the initial investment in automation may seem steep, the long-term benefits—including reduced labor costs, faster production cycles, and higher output—quickly justify the expense. For businesses using solutions like “tools today CNC machine” setups or even “used CNC machine tools,” automation ensures they remain competitive in an increasingly fast-paced industry.

The realization of CNC automation

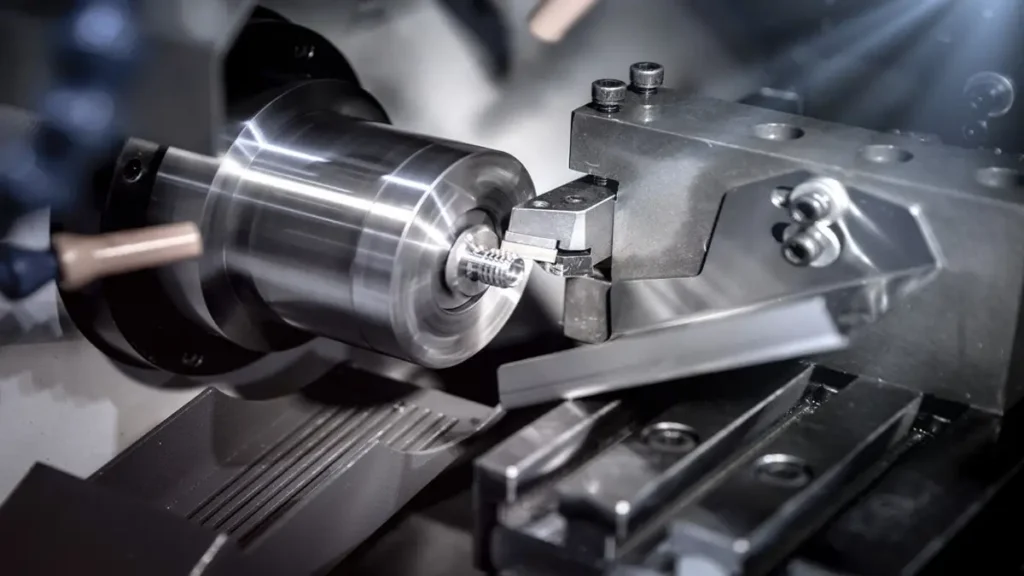

So, how do manufacturers bring CNC automation to life? It starts with integrating cutting-edge technologies like robotic arms, automated tool changers, and intelligent software systems. Picture this: a robotic arm seamlessly loading raw materials into a CNC machine while simultaneously managing “tools used in CNC machine” operations such as tool changes and part inspections. These robots are not just efficient—they’re tireless workers that execute repetitive tasks with unerring consistency.

Modern CNC machines also come equipped with advanced features like automatic probing systems for precise measurements and chip-clearing mechanisms to ensure uninterrupted operation. These innovations allow manufacturers to handle complex tasks with ease while maintaining exceptional accuracy and efficiency.

Real-time monitoring tools are another cornerstone of CNC automation. These systems track critical parameters such as tool wear, cutting conditions, and machine performance, enabling predictive maintenance that minimizes downtime. Whether you’re working with “stone machinery CNC machine tools” or other types of advanced equipment, these technologies ensure smooth operations and maximum productivity.

For example, companies like Haas Automation have pioneered user-friendly interfaces that allow operators to program machines quickly while monitoring performance metrics in real time—a feature that’s particularly useful for small businesses looking to scale without compromising on quality.

Integrated manufacturing technology

Automation doesn’t just transform individual machines—it revolutionizes entire manufacturing ecosystems through Computer-Integrated Manufacturing (CIM). CIM connects processes such as design, production planning, quality control, and inventory management into one cohesive system. Think of it as an orchestra where every instrument plays in perfect harmony to create a symphony of efficiency.

For instance, CIM systems can dynamically adjust production schedules based on real-time data from supply chains or customer orders. This level of responsiveness ensures that resources are allocated efficiently while minimizing delays or bottlenecks. By combining robotics with enterprise resource planning (ERP) software, manufacturers gain granular control over inventory levels and production analytics—empowering them to make data-driven decisions that improve profitability.

This approach is particularly valuable for companies utilizing diverse “types of CNC machine tools” across various stages of production. Whether machining metals for aerospace components or plastics for consumer electronics, CIM ensures seamless coordination between processes for optimal results.

CNC machines play a key role in automating the automotive manufacturing industry

The automotive industry has embraced CNC automation to produce high-precision components such as engine blocks, transmission gears, and suspension parts. With the growing demand for lightweight vehicles to improve fuel efficiency and reduce emissions, materials like aluminum have become increasingly popular—and CNC machines excel at machining them with unparalleled precision.

Automation allows manufacturers to meet tight tolerances while significantly reducing cycle times. For example, automated milling machines can produce intricate engine components with exceptional repeatability—a critical requirement when manufacturing millions of identical parts for mass-market vehicles.

Additionally, automated tool changers enable seamless transitions between tasks like drilling and grinding without manual intervention. This capability is invaluable when producing complex assemblies that require multiple machining processes in quick succession.

By leveraging “tools today CNC machine” setups tailored specifically for automotive applications, manufacturers can adapt quickly to changing industry demands—whether it’s producing electric vehicle (EV) components or scaling up production for new car models.

How do you handle multiple materials in automotive manufacturing

One of the most remarkable capabilities of CNC machining is its versatility in handling diverse materials—a crucial advantage in automotive manufacturing where different materials are used for various components:

- Metals: Aluminum is widely used for engine parts due to its lightweight properties and machinability; steel is preferred for components requiring strength and durability.

- Plastics: Materials like ABS are ideal for interior parts because they are cost-effective yet durable enough to withstand wear and tear.

- Composites: Advanced composites are increasingly used in electric vehicles (EVs) thanks to their superior strength-to-weight ratio.

Automated CNC systems equipped with specialized tools can switch effortlessly between these materials without compromising on quality or precision—a game-changer when working on complex assemblies like car chassis or battery enclosures.

Even “used CNC machine tools” equipped with modern upgrades can deliver excellent performance when handling such diverse materials. This makes automation accessible even to smaller manufacturers looking to optimize their operations without investing heavily in brand-new equipment.