If you’ve ever paid attention to the automation revolution in manufacturing, you know that the CNC machines is a true “superhero” of modern industry. But did you know that one of its “superpowers” lies in the design and configuration of its rotary axes? Rotary axes don’t just determine machining flexibility—they directly impact precision and efficiency. Imagine a CNC machine as a robot that can only move in straight lines; without rotary axes, it would struggle to handle complex curves and multi-angle operations.

In this article, we’ll explore the core types of rotary axis configurations in CNC machines. Whether you’re a decision-maker or a technician, understanding these options will help you make smarter choices when selecting or customizing a CNC machine. Ready to dive in? Let’s explore the world of rotary axes together!

Overview of CNC Machines Axes

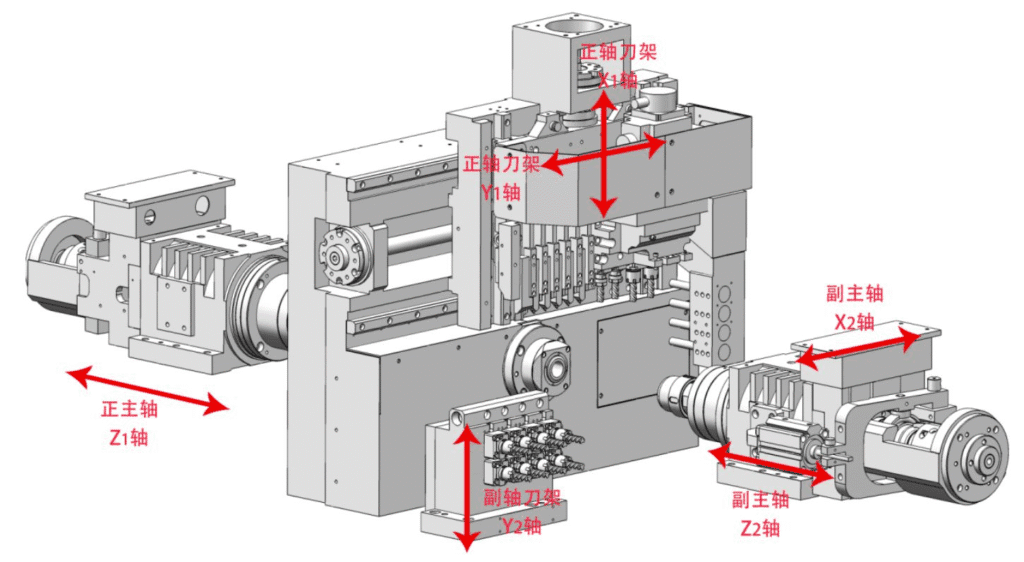

In the world of CNC machines, axes are the foundation of movement. Simply put, there are two main types:

- Linear Axes: Typically X, Y, and Z axes, responsible for straight-line movement.

- Rotary Axes: Such as A, B, and C axes, responsible for rotating either the workpiece or the tool.

Linear axes position the machine in three-dimensional space, while rotary axes give the CNC machine the ability to work at multiple angles and on multiple faces. The addition of rotary axes is what enables CNC machines to produce complex parts.

Detailed Look at Core CNC Machines Rotary Axes

A Axis (Rotation Around the X Axis)

- Applications: Surface machining, tube engraving, camshaft production

- Advantages: Reduces the number of setups, increases machining efficiency

Imagine you need to engrave intricate patterns on a cylinder. The A axis allows the workpiece to rotate around the X axis, letting the tool approach from different angles and saving valuable time.

B Axis (Rotation Around the Y Axis)

- Applications: Angle cutting, turbine blade manufacturing, complex angle machining

- Advantages: Enables multi-angle cutting, enhances complex part production

With the B axis, the machine can handle angled and non-vertical machining, making it ideal for aerospace and automotive industries.

C Axis (Rotation Around the Z Axis)

- Applications: Circumferential machining, gear cutting, mill-turn operations

- Advantages: Increases multi-face machining efficiency, simplifies processes

The C axis allows the machine to rotate the workpiece like a lathe, which is perfect for advanced mill-turn processes.

Common CNC Machines Rotary Axis Configurations

| Configuration Type | Rotary Axis Combination | Typical Applications | Advantages |

|---|---|---|---|

| 4-Axis CNC Machine | X, Y, Z + A or C Axis | Complex surfaces, cylindrical parts | Greater flexibility and efficiency |

| 5-Axis CNC Machine | X, Y, Z + A+B or A+C Axes | High-precision complex parts, molds, aerospace | Multi-angle, high-precision machining |

Choosing the right rotary axis configuration can dramatically boost your machining capabilities and help you meet more customer needs.

Guide to Choosing the Right Rotary Axis Configuration

You might be wondering: “Which rotary axis configuration is right for my factory?” Here are some tips:

- Based on part shape and complexity: For simple parts, 4 axes are usually enough. For complex molds or aerospace components, 5 axes are recommended.

- Consider machining precision: High-precision parts require a more stable rotary axis system.

- Budget and productivity: Multi-axis machines are a bigger investment, but they significantly improve efficiency and reduce labor costs.

With these points in mind, you’ll be able to make the best choice for your needs.

How Rotary Axis Configuration Impacts CNC Machine Performance

The right rotary axis setup brings several benefits:

- Improved machining accuracy: Multi-angle operations reduce errors.

- Greater process flexibility: Handle more complex shapes.

- Less manual intervention: Fewer setups save time and labor.

- Higher automation: Ideal for smart manufacturing and batch production.

Want your factory to be more efficient and intelligent? Rotary axis configuration is the key.

Now you have a comprehensive understanding of core rotary axis configurations in CNC machines. The right choice can enhance both efficiency and precision, helping you stay ahead in a competitive market. In today’s manufacturing world, a well-configured multi-axis CNC machine is a major step toward high-quality growth.

If you’re looking for high-performance CNC machines or want to customize a rotary axis setup to fit your needs, contact us today. Let’s work together to build a smarter, more efficient future for your production!

Don’t wait—take action now and upgrade your manufacturing power!