What is CNC Machine Tools

CNC machine tools MR35-5Ⅱ short for Computer Numerical Control machine tools, are advanced manufacturing devices that rely on pre-programmed computer software to control the movement of machinery and tools. These machines are essential in industries such as aerospace, automotive, and electronics, where precision and efficiency are critical. From compact options like the Bantam Tools Desktop CNC Milling Machine, ideal for small-scale projects, to industrial-grade systems such as Laguna Tools CNC Machines, CNC tools cater to a wide range of manufacturing needs.

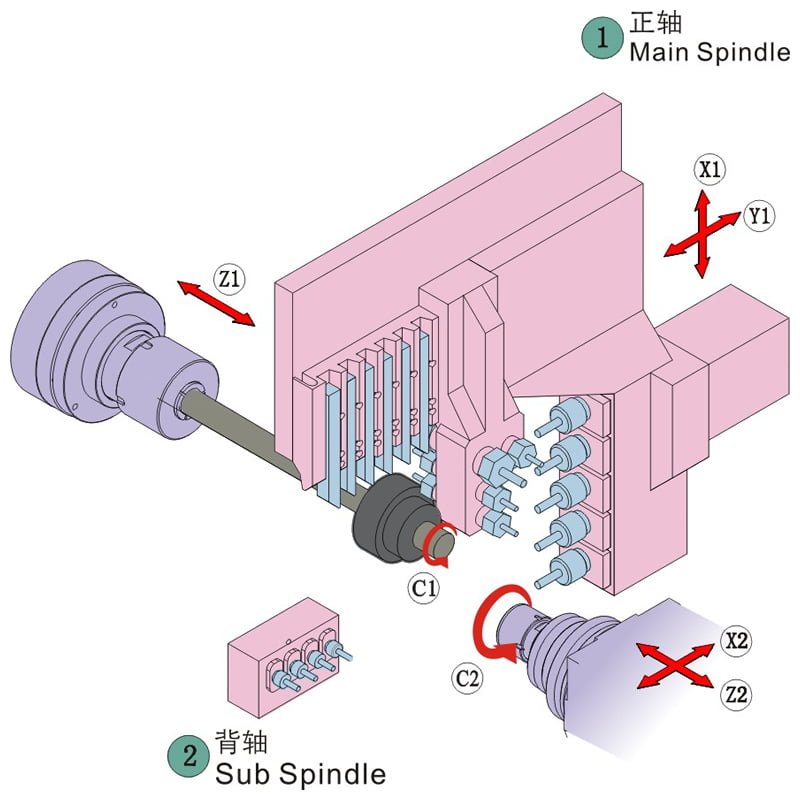

Unlike traditional manual machines, Dual spindle centering machine MR35-5Ⅱ CNC tools automate the entire production process. This ensures consistency, accuracy, and efficiency while minimizing human error. They handle tasks like milling, turning, drilling, and grinding with incredible precision. Whether you’re searching for “CNC machine tools near me” or exploring high-tech solutions for your business, CNC technology has transformed modern manufacturing into a streamlined and highly reliable process.

Main Advantages of CNC machine tools MR35-5Ⅱ

The advantages of CNC machine tools go far beyond simple automation. Let’s dive into why they’re indispensable:

- High Precision and Consistency

Imagine producing thousands of identical parts with no variation—this is what CNC machines excel at. With micron-level accuracy, they ensure every piece meets strict specifications. For example, Laguna Tools CNC Machines are widely praised for their ability to deliver flawless results in demanding industries like aerospace and automotive. - Increased Production Efficiency

Time is money in manufacturing. CNC machines significantly reduce production time by automating complex tasks that would otherwise require hours of manual labor. Even smaller devices like the Bantam Tools Desktop CNC Milling Machine can handle intricate designs quickly without sacrificing quality. - Versatility Across Applications

A single CNC machine can perform multiple operations—cutting, drilling, engraving—all without needing separate setups. Whether you’re crafting custom furniture or machining metal engine parts, these machines adapt to your needs effortlessly. - Reduced Labor Costs

With automation at the core, fewer operators are needed to oversee production. This allows businesses to allocate resources toward innovation or other high-value activities. - Ease of Repetition and Programmability

Once programmed, a CNC machine can repeat tasks indefinitely with zero deviation. This makes it ideal for batch production or manufacturing components that require consistent quality over time.

Ultimately, whether you’re running a small workshop searching for “CNC machine tools near me” or managing a large-scale factory, the benefits of CNC technology make it a game-changer for modern manufacturing.

Features and Functions

CNC machine tools stand out because they merge mechanical engineering with computer technology to create a powerful manufacturing solution. Here’s what makes them unique:

- Automated Operation: By using programming languages like G-code to control tool paths, CNC machines eliminate human error and ensure precise execution.

- Efficient Multi-Tasking: For instance, CNC milling machine tools can simultaneously cut intricate shapes while maintaining tight tolerances.

- Multi-Axis Control: Modern machines support multi-axis motion (e.g., 3-axis, 5-axis), allowing them to create complex geometries that were once impossible with traditional methods.

- Real-Time Monitoring and Adjustments: Advanced sensors continuously track performance metrics like speed and temperature, enabling real-time corrections that prevent defects.

- Material Versatility: Whether you’re working with metals, plastics, or wood, CNC machines can handle almost any material with ease.

For example, an artist might use a desktop CNC milling machine to carve intricate patterns into wood for custom furniture designs. Meanwhile, an aerospace engineer could rely on a 5-axis Laguna Tools CNC Machine to create turbine blades with unparalleled precision.

Components of CNC and Their Functions

Understanding the key components of a CNC machine helps you appreciate how these systems work together seamlessly:

- Controller (The Brain)

The controller interprets programming instructions (often written in G-code) and directs the machine’s movements accordingly. Modern controllers feature user-friendly interfaces that simplify operation even for beginners. - Spindle (The Workhorse)

The spindle drives cutting tools at high speeds to execute machining tasks like drilling or milling. Its power determines how efficiently the machine can cut through tough materials. - Tool Changer (The Organizer)

This component stores multiple cutting tools and switches between them automatically during operations. For instance, when using different types of CNC machine measuring tools, the tool changer ensures seamless transitions without manual intervention. - Worktable (The Foundation)

The worktable supports the material being machined and keeps it stable during operations. Some advanced models include rotary tables for multi-angle machining. - Servo Motors & Drives (The Movers)

These components control precise movements across various axes (X, Y, Z), ensuring high accuracy even during complex tasks. - Cooling System (The Protector)

Machining generates heat that can damage tools or materials if unmanaged. Cooling systems prevent overheating and extend both tool life and product quality.

Together, these components enable machines like the Laguna Tools CNC Machine to deliver exceptional performance across diverse applications—from prototyping to mass production.

How to Evaluate the Performance and Durability of CNC machine tools MR35-5Ⅱ

Choosing the right CNC machine requires careful consideration of several factors:

- Accuracy and Repeatability

Can the machine consistently meet your required tolerances? High-end models like Laguna Tools excel in delivering precision suitable for industries where even minor deviations are unacceptable. - Build Quality

Machines built with heavy-duty steel frames offer greater stability than those made from aluminum. For long-term durability under demanding workloads, prioritize robust construction. - Software Compatibility

Ensure your chosen machine integrates seamlessly with CAD/CAM software or specialized tools like CNC machine measuring tools, which help maintain dimensional accuracy during production. - Ease of Maintenance

Look for machines that are easy to clean and maintain over time. Smaller options like Bantam Tools’ desktop models often require less upkeep compared to industrial-grade systems. - Cost vs Performance

Balance your budget against your needs—while premium machines offer advanced features, smaller workshops might benefit more from affordable local options when searching “CNC machine tools near me.”

By evaluating these factors thoroughly, you’ll find a machine that not only meets your current requirements but also grows with your business over time.

FAQ

What is the best small-scale CNC machine for beginners?

Beginners should consider compact devices like the Bantam Tools Desktop CNC Milling Machine—it’s user-friendly yet powerful enough for learning and small projects.

How do I maintain my CNC machine?

Regular cleaning, lubrication checks, and component inspections are essential for keeping your machine in top condition. Always follow the manufacturer’s maintenance guidelines for optimal performance.

What industries use Laguna Tools CNC Machines?

Laguna Tools serves industries ranging from woodworking to metal fabrication and composite material manufacturing—making it popular among professionals seeking versatility and reliability.

Where can I find “CNC machine tools near me”?

Local suppliers or industrial trade shows are great starting points when searching for nearby vendors who can provide faster service support if needed.

What are CNC machine measuring tools?

These tools—such as probes or laser measurement devices—are used to calibrate workpiece dimensions during machining processes. They help ensure precision while reducing waste by identifying errors early on.