Have you ever wondered why modern manufacturing with 3-axis CNC lathe is so efficient and precise, even for complex machining tasks? One of the key answers lies in the advanced turret/tool post system. This system acts as the “commander” of the machine tool, responsible for fast and accurate tool changes, ensuring smooth and error-free machining.

As the core component of a 3-axis CNC lathe, the turret/tool holder system affects machining efficiency as well as product quality and machine service life. Today, let’s take a deep dive into the structure, working principles, and selection tips for this system. This knowledge will help you better appreciate its value and even provide ideas for upgrading your production line.

Basic Concepts of Turret/Tool Post System

First, what exactly are a turret and a tool post? And what’s the difference between them?

- Turret: Usually refers to a rotating device with multiple tool positions, allowing for quick tool changes.

- Tool Post: The support that holds the tool in place. Sometimes the concepts of turret and tool post overlap, but the tool post emphasizes the fixed position of the tool.

In simple terms, the turret/tool post system is the “toolbox” of the machine, enabling flexible tool changes to handle different machining tasks.

Structure of the Turret/Tool Post System in 3-Axis CNC Lathe

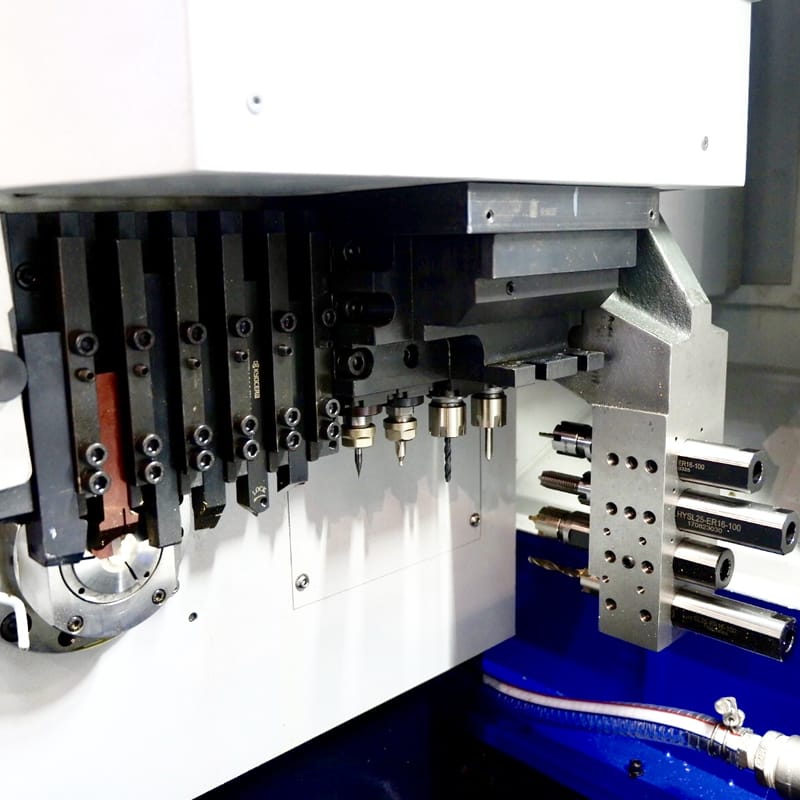

The turret/tool post system is not a simple part-it consists of several key components:

- Turret Body (Tool Disc): The main rotating part with multiple tool positions.

- Drive Mechanism: Includes electric motors, hydraulic systems, or servo motors that rotate and position the turret.

- Positioning Mechanism: Ensures the turret stops precisely at the correct tool position during tool changes.

- Clamping Device: Locks the tool in place to ensure stability during machining.

Depending on machine requirements, turret/tool post structures vary. Common types include:

- Electric Tool Post: Simple structure, low cost, suitable for economical machines.

- Hydraulic Turret: Fast tool changes, high rigidity, ideal for heavy-duty cutting.

- Servo Turret: High positioning accuracy, suitable for advanced and complex machining.

The number of tool positions also varies, from 4 to 16 or more, to meet different levels of machining complexity.

Working Principle of the CNC lathe Turret/Tool Post System

Tool changing may sound simple, but it involves a precise process:

- Lifting the Tool: The turret lifts the current tool to avoid interference with the workpiece or machine bed.

- Rotating the Turret: The drive mechanism rotates the turret to the target tool position.

- Positioning: The positioning mechanism ensures the turret stops precisely at the selected position.

- Clamping the Tool: The clamping device locks the tool securely for stable machining.

The control system (usually CNC) coordinates all these actions, working with the servo motor for fast and accurate tool changes. Sometimes, the system uses the “shortest path tool selection” to minimize turret rotation and boost efficiency.

Performance and Advantages of the Turret/Tool Post System

You might ask, “Why should I care about choosing the right turret/tool post system?” Here are some key reasons:

- High Positioning Accuracy: Ensures the tool is always in the correct position, maintaining machining consistency.

- Excellent Rigidity: A robust turret structure reduces vibration and improves machining quality.

- Fast Tool Changes: Shorter tool change times mean higher production efficiency.

- Multiple Tool Positions: Supports the installation of various tools for complex machining needs.

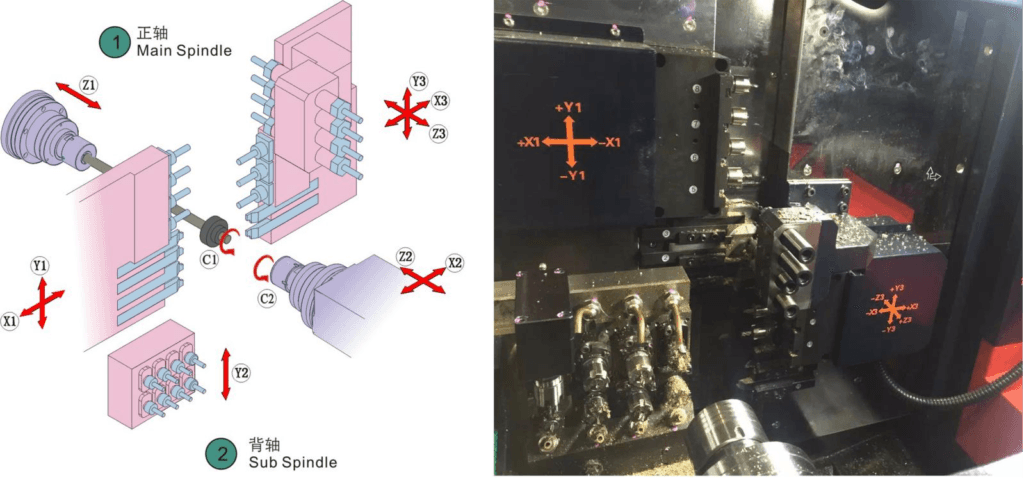

Additionally, power turrets can drive powered tools for milling, drilling, and other compound machining, greatly expanding the machine’s capabilities.

Comparison of Common CNC lathe Turret/Tool Post Types

Here’s a quick table to help you understand the features of different turret types:

| Type | Tool Change Method | Tool Positions | Application Scenario | Main Advantages |

|---|---|---|---|---|

| Electric Tool Post | Electric | 4-8 | Economical CNC lathes | Simple structure, low cost |

| Hydraulic Turret | Hydraulic | 8-12 | Heavy-duty, high rigidity | Fast tool change, high rigidity |

| Servo Turret | Servo Motor | 8-16+ | High-end CNC lathes | High accuracy, flexible tool selection |

| Power Turret | Servo/Hydraulic | 12-16+ | Compound machining | Can drive powered tools |

Choosing the right turret type lets your machine reach its full potential.

Selection Tips for Turret/Tool Post Systems

When selecting a turret/tool post, consider the following:

- Machining Needs: Is it light or heavy-duty? Do you need compound machining?

- Number of Tool Positions: More complex machining requires more tool positions.

- Positioning Accuracy and Rigidity: For high-precision work, choose a servo or power turret.

- Budget: For economical machines, electric tool posts are suitable; for higher performance, go for servo or hydraulic turrets.

- Brand and After-Sales Service: Well-known brands offer mature solutions and better support.

Still unsure? Contact us! We can recommend the most suitable turret/tool post system based on your specific needs.

Maintenance and Common Troubleshooting for Turret/Tool Post Systems

Maintaining the turret/tool post system is actually quite simple:

- Regular Lubrication: Keeps moving parts smooth and extends service life.

- Check Fasteners: Prevents looseness that could affect positioning accuracy.

- Remove Debris: Keeps dust and chips from interfering with tool changes.

- Monitor Tool Change Sounds: Unusual noises may indicate wear or faults.

Common issues include inaccurate tool changes, loose tool clamping, or turret rotation jams. Timely inspection and repair can prevent production downtime.

The turret/tool post system is the “heart” of a 3-axis CNC lathe. It determines tool change speed, machining accuracy, and overall efficiency. Choosing the right turret system not only improves machining quality but can also significantly reduce production costs.

Looking ahead, as smart manufacturing advances, turret/tool post systems will become even more intelligent and multifunctional, helping the industry reach new heights.

Want to learn more about multiaxis machines and their components? Visit our website and let’s start a new chapter of efficient machining together!